Recycling lithium batteries could be worth $100bn per year by 2040 while supporting electric vehicles’ ascent. Hence new companies are emerging to recapture 95% of spent materials with environmentally sound methods. To be practical, the technology needs to be proven at scale, battery chemistries must stabilize and cheaper alternatives must be banned. Our 15-page note explores what it would take for battery-recycling to get compelling.

There are three aspirations for recycling electric vehicle batteries. They are outlined on pages 2-6, including an overview of future market sizing and companies.

How does it work? We have summarized the basic process for pyrometallurgical and hydrometallurgical recycling on pages 7-10, condensing the most helpful data-points from reviewing half-a-dozen technical papers.

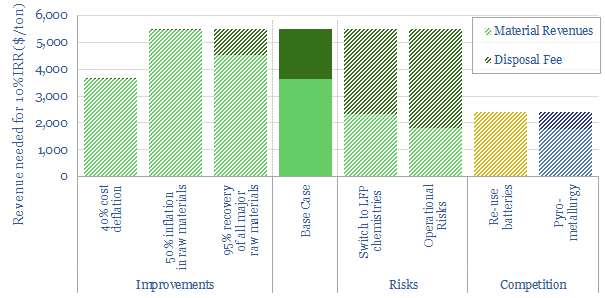

The economics are outlined on pages 11-13, as we have modelled a hydrometallurgical facility that achieves c70% recovery of overall input materials, as our base case. Our commentary focuses on the best opportunities for cost deflation.

To get particularly excited by battery recycling, we would need to see improvements around half-a-dozen question marks, which are spelled out on pages 14-15.