24M was founded in Cambridge, MA in 2010, spinning out of MIT. It now has over 100 employees and has raised over $100M in venture investments. It is licensing a “semi-solid” lithium ion battery technology, offering greater energy density and lower costs. It is the main technology provider for Freyr, Kyocera’s Enerezza product line, and being fine-tuned for use in Volkswagen’s electric vehicles, under a 2021/22 deal where the auto-maker took a 25% stake in 24M. This data-file is a 24M battery technology review.

Semi-solid electrodes are aimed at “dramatically reducing” costs of lithium ion batteries, with higher energy density, safety and reliability, for use in battery storage (to replace gas peakers) and in electric transportation solutions. The process requires 50% less capex versus a conventional manufacturing line, mixing active materials in a clay-like slurry, and a dry coating process. Next-generation research is looking to couple the cells with lithium anodes for electric aviation.

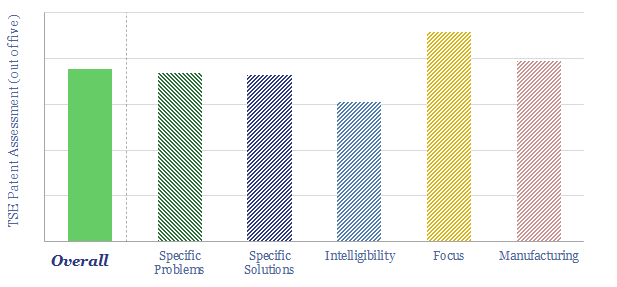

Our patent review focuses in on a sample of c15 out of c50 distinct patents that 24M has filed. This clearly shows how the technology improves upon the prior art. Specifically, the traditional method for manufacturing battery electrodes is to coat a metallic current collector with a solution. The solvent is commonly N-methyl-pyrrolidone. As it evaporates, a thin layer remains, including the active materials and a ‘binder’ that acts as a glue. A common binder is polyvinylidene difluoride. The first drawback is that the electrode layer is thin (<100μm), whereas thicker materials can store more energy. The second drawback is that the binder does not store energy, it may even block energy from flowing (tortuosity), while it adds mass, volume and potential degradation pathways (oxidizing). The third issue is that evaporating the solvent and post-processing the material is time-consuming and complex.

24M battery technology review. Overall, 24M’s patents explain why large battery companies have licensed its simpler, more energy dense, lower-degradation battery manufacturing technology; the general workings of which are locked up for at least another decade. We see a moat and can partially de-risk the scale-up of semi-solid electrodes. However, we think there is one technical challenge that decision-makers should still factor in, plus three smaller risks.