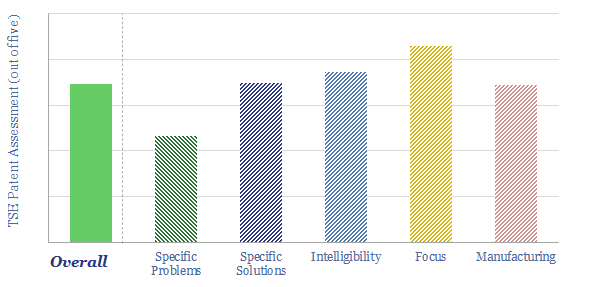

This data-file is a review of Agilyx’s plastic recycling technology, after assessing the company’s patents on our usual framework. We conclude that Agilyx has developed a novel and data-driven process, to remove challenging contaminants from feedstocks. Although it may involve higher complexity, higher reagent opex, and some challenges cannot entirely be de-risked from the patents.

Agilyx is a public company listed on the Oslo Euronext Growth, headquartered in Oslo, Norway, with presence in New Hampshire, Oregon, Switzerland and Denmark. The company has 90 employees at YE21.

Its commercial model is to license IP for categorizing thousands of different types of post-consumer plastics (on a royalty basis per kg), license its conversion technology for subsequent pre-processing and pyrolysis of those waste plastics, and also to sell patented equipment.

Agilyx’s long-term mission is to help increase the world’s share of 300MTpa of recycled plastic waste from 10% to 90%. Along the way, its goal is to be the “fastest growing and most profitable plastic recycling technology company”. The synthetic crude oil thereby created is envisaged to be lower carbon than conventional crude oil or virgin feedstock.

As its moat, Agilyx states “we are the only company in the market to offer an integrated solution for chemical recycling and feedstock management… [including] a proprietary technology for identifying, managing and pre-processing [plastic] waste” then breaking it down into synthetic crude oil using a pyrolysis process.

This data-file is a review of Agilyx’s plastic recycling technology. Based on its patents, we infer that Agilyx has developed an intriguing and novel approach to plastic recycling. We think it uses a large database to identify likely hetero-atom contaminants in mixed plastic waste, tailors alkali amendments to those contaminants prior to the pyrolysis stage, pyrolyses the mixture, quenches cracked gaseous hydrocarbons from the reactor, then polishes the depolymerized hydrocarbons by passing them through caustic process solutions that remove impurities. This is explained in the data-file.

However, we cannot entirely de-risk the technology based on the patents, while there are also some challenges from the patent library, including around operating conditions, complexity and operating costs. We have been following the next-gen plastic recycling theme since 2019. There is extremely exciting potential for plastic pyrolysis, but mixed progress to-date, including in 2022. Further and broader details are found in our plastic research.