Bio-coke is a source of carbon and energy for steel-making, and other smelting operations where metal oxides need to be reduced to pure metals.

Bio-coke differs from conventional coal-coke or petcoke in that it is derived from biomass, ideally waste biomass, which would otherwise have decomposed. This lowers emissions.

Specifically, input materials are treated at high temperatures and pressure (sometimes around 1,000ºC) to drive off non-carbon materials as gases and ashes.

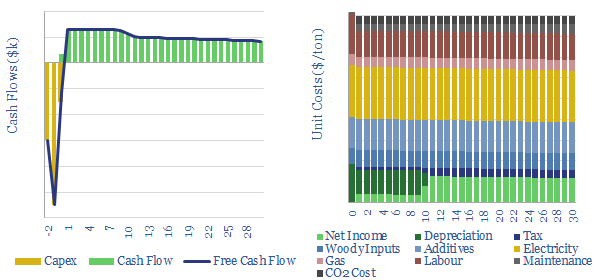

Bio-coke energy economics. Costs of bio-coke production will most likely run at $450/ton, in order to earn a 10% IRR on a greenfield facility, per the calculations in this model. This is c50% more than the typical price of $300/ton for coal-coke, in normal times. But the higher cost may be economically justified…

Total CO2 intensity of producing bio-coke is calculated at 1 – 1.5 tons/ton, as quantified from technical papers and our own estimates in this data-file. Hence it would save around 2 – 3 tons/ton of CO2 compared with coal-coke. CO2 abatement costs are therefore implied to run at $70/ton, which is competitive on our roadmap to net zero.

However, bio-cokes are not directly comparable with coal-cokes. For example, bio-cokes might have an energy density above 5,000 kWh/ton and “fixed carbon” of 25-85%, a broad range depending on processing parameters. By contrast, traditional coke is closer to 7,000-8,000 kWh/ton, and always above 80% carbon. In addition, bio-cokes can be 50-75% softer and more reactive in some furnace designs than traditional coke. This requires plant modifications, additives and binders, which are still being de-risked.

There are also challenges for scaling. Near-term bio-coke production facilities are likely operating with scales of tens of kTpa. One of the larger operations today, situated in Brazil, makes 600kTpa of ‘zero carbon’ steel, which itself requires 50,000 hectares of planted eucalyptus. However, the total global steel industry produces 2GTpa of output, and replacing all of its coal and coke with biomass could require 2GTpa of biomass inputs, equivalent to the world’s total global timber harvest.

Overall, we conclude that there are good opportunities for bio-coke to contribute to decarbonization of metals and materials, as one out of many concurrent opportunities. Although we might still prefer adjacent opportunities in biochar. You can stress test broad-ranging input variables for bio-coke energy economics in this model.