The data-file gives an overview of different gas-sweetening and gas-processing operations, outlining the process, indicative costs, and drawbacks. We also note 20 companies with gas treatment technologies, although our list is by no means exhaustive.

Gas sweetening may be particularly important as global gas demand trebles in our roadmap to net zero and to remove H2S and CO2 from growing volumes of biogas.

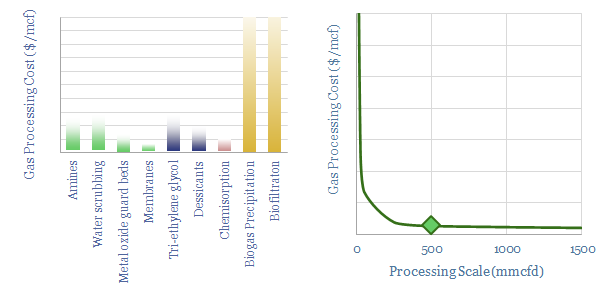

The main method used for conventional gas-sweetening is chemical absorption using amines. We estimate that a mid-size facility of 500mmcfd capacity must levy a $0.15/mcf gas treatment cost and emit around 3.5kg/boe, to take out c7% H2S and CO2 from the mix.

Small-scale biogas technologies can be an order of magnitude more expensive, especially for early-stage biological processes being explored.

Other technologies in the data-file include wet-scrubbing using solvents, membranes, metal oxide guards, swing absorption and water removal.