Howmet is an engineered metals company, and the world’s #1 supplier of airfoils (blades and vanes) for jet engines and gas turbines. The company has claimed an edge in direct-casting cooling channels (rather than drilling them) and bond coats that improve the adherence of Thermal Barrier Coatings. Our Howmet gas turbine technology review found support for these claims, via reviewing a dozen patents.

Howmet Aerospace is a US engineered metals company, which goes back to 1888, has 23,200 employees, and is listed on NYSE.

Howmet’s business is c50% engine products (in turn, 70% of which comprise blades and vanes for both jet engines and gas turbines, where it is the world’s #1 supplier), 20% fastening systems, 15% engineered structures and 15% forged wheels.

Our recent work has argued that the global gas turbine market will double from 50 GW pa in the past five years to 100 GW pa in the 2024-30 timeframe, and in turn, our cost breakdown of a gas turbine ascribes about 20% of total installed costs to engineered metal components such as blades, vanes, rings, seals, bearings, nozzles, guides and fasteners.

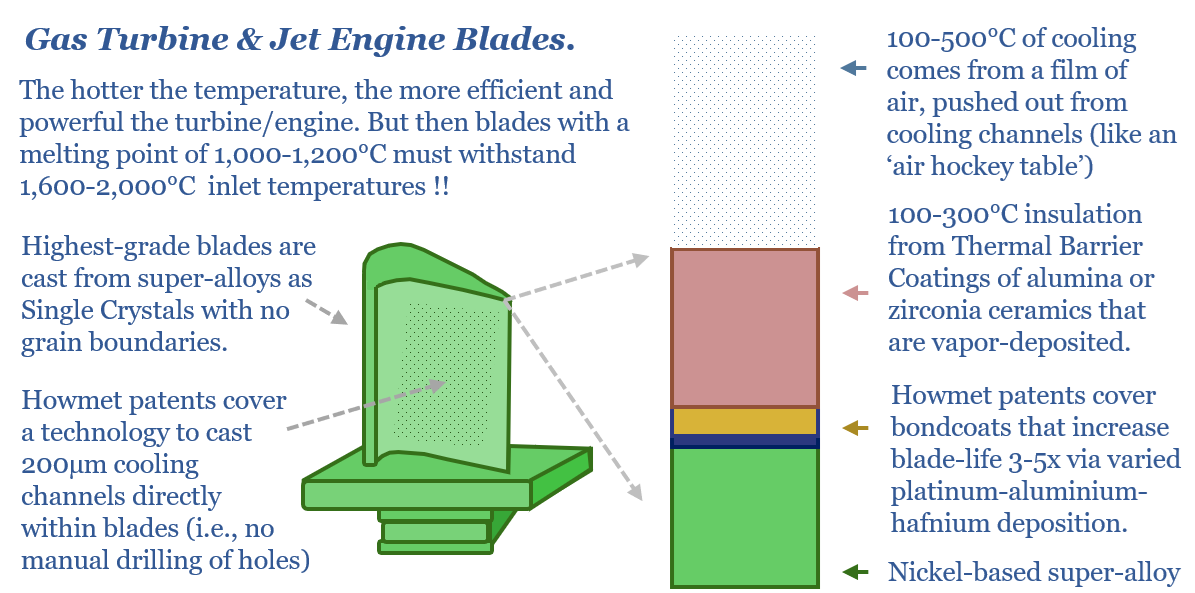

The laws of thermodynamics dictate that hotter inlet temperatures will lead to more efficient and more powerful turbines, both in jet engines and in gas turbines. But very hot metals tend to deform and melt, even when made from super-alloys.

Howmet has claimed an edge in manufacturing engine and turbine components, hinging on the ability to cast (rather than drill) cooling channels, improve the adherence of Thermal Barrier Coatings to metals using bondcoats, and via automating high-labor operations.

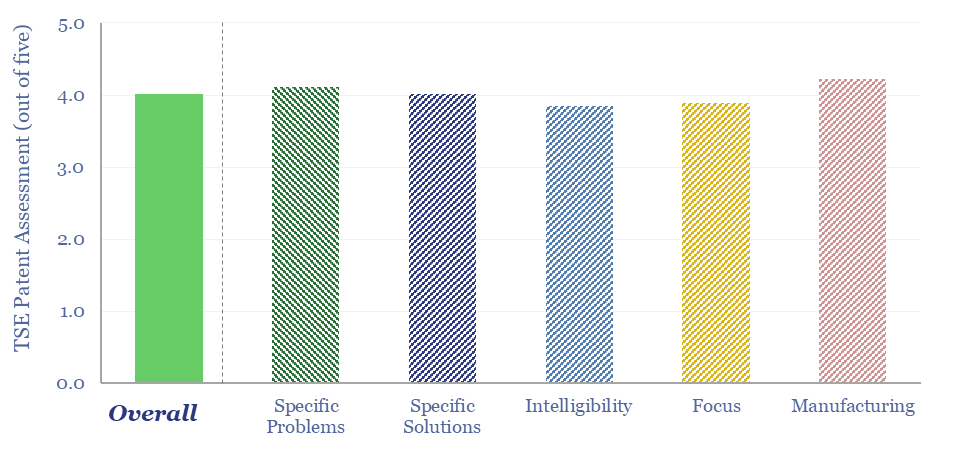

Our Howmet gas turbine technology assessment found strong support for these claims, with key patents locking up cast cooling features, platinum-aluminium-hafnium bond coating ‘recipes’. Full details are in the data-file, including our best guesses on the patent expiry timings.

It was also interesting to note that Howmet’s products are essential to the F-35 fighter jet, lighter aircraft with >50% carbon fiber use 2-3x higher-value fasteners, Howmet’s largest Forging Press is 50,000 tons and 10 stories tall, while Howmet is also the largest producer of forged aluminium wheels that are 45% lighter than steel, improving fuel efficiency by 5% and/or 3% greater payload capacity on 18-wheeler trucks.

Advanced metal businesses might be considered an example of companies meeting the triple challenge of energy transition.