The data-file captures the economics of hydroprocessing at an oil refinery, such as hydrotreating or hydrocracking, to remove impurities such as sulphur, and upgrade heavier product into lighter product.

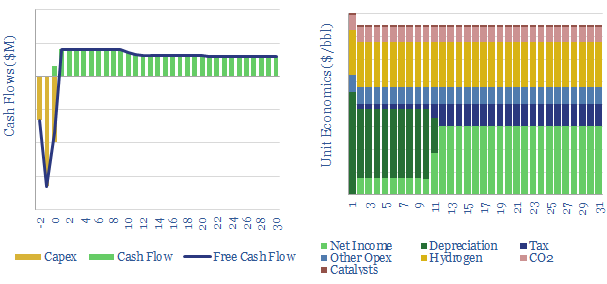

Our base case model requires a $7.5/bbl upgrade spread to earn a 10% IRR across a new unit. CO2 emissions are quantified from hydrogen production. Input assumptions are based on past projects and technical papers, including capex costs (in $M/kbpd) and hydrogen utilization (in scf/bbl).

It is possible to decarbonize hydroprocessing by using green hydrogen instead of grey hydrogen, but the result is a 3x increase in the upgrading spread required for economical running of the unit.