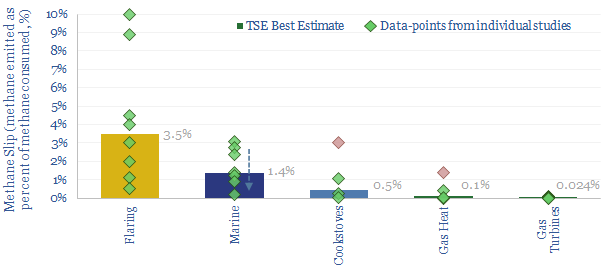

Methane slip occurs when a small portion of natural gas fails to combust in a boiler, burner, engine or turbine, and instead escapes into the atmosphere. How much methane leaks? This data-file reviews technical papers. Methane slip is very low at gas turbines and gas heating (less than 0.1%), rising to 0.5 – 3% in cookstoves and some dual-fuel marine engines. However, the highest rate of methane slip occurs in flaring.

Methane is a potent greenhouse gas, with a global warming potential that is 100x CO2 on a 20-year basis and 28.5x CO2 on a 100-year basis. Our roadmap to net zero requires ramping natural gas but also mitigating methane leaks.

Methane slip is a category of methane leakage at the point of consumption. Specifically, methane slip occurs when natural gas is supplied to a boiler, burner, engine or turbine, but fails to combust, and instead, methane is released uncombusted into the atmosphere.

The purpose of this data-file is to review different technical papers into methane slip, in order to quantify the most likely methane emissions rates by end use category. Three general observations are that (a) methane slip at the point of end consumption seems to have been less well researched than methane leakage throughout the supply chain (b) there can be a wide variation in different studies’ findings and (c) studies with the most extreme results have tended to receive the most media attention (go figure).

Modern gas turbines in the power sector have the lowest methane slip, estimated at 0.02% on average, according to data accepted by the EPA and IPCC. In the best study that crossed our screen, researchers from Purdue, Harvard, Environmental Defense Fund and Scientific Aviation flew 23 flights over 14 natural gas power plants. Some of the readings in the study actually came in “negative”. I.e., the air above the gas turbines was depleted in methane relative to the broader atmosphere, which was attributed to “partial combustion of ambient CH4 in the power plant”. Very low rates of methane slip in natural gas power plants can be attributed to high temperatures and continuous combustion, or in other words, the thermodynamics of the Brayton Cycle. Although slippage rates are higher when turbines first start up, or when they are throttled aggressively in volatile power grids.

Gas heaters and boilers most likely have a methane slip rate of 0.1%. However, what stood out from our review of technical papers was the skew. One study reviewed the methane leakage from gas-consuming devices in 75 Californian homes, and found a median leakage rate of <0.01%, a mean of 0.136% and a maximum of 1.0%. There is almost certainly a “tail” of defective heaters and boilers that needs to be identified and repaired.

Marine engines are increasingly using LNG as a transportation fuel, where the chemical properties of natural gas result in 24% lower emissions than heavy fuel oil (data here). Around 700 LNG-fueled vessels are in use globally in 2022. The rates of methane slip are much higher in some of these reciprocating engines than in gas turbines. The reason is that each stroke of a reciprocating engine is discrete, with the chance for injected fuel to ‘hide’ in the cold spots of engine cylinders, or pass directly from the injection valve to the exhaust valve. However this is being addressed. Wärtsilä has reduced methane slip from its dual-fuel engines by 85% since 1993, from 16 g/kWh to 2-3 g/kWh and says the next generation of engines will slip 1 g/kWh.

The highest rate of methane slip is in natural gas flaring, where our mid-point estimate is around 3.5% of the gas, but some studies have estimated leakage rates as high as 10%. Especially during high wind speeds, there is a danger that methane escapes the flare, or worse, that the flare is blown out, like a kind of environmentally unfortunate birthday cake. Overall the data suggest that reducing flaring (e.g., via gas utilization) and improving flaring are the world’s ‘lowest hanging fruit’ to reduce methane slippage. Companies such as Capterio, Baker Hughes, Sensia and Cimarron Energy have developed interesting solutions.