Prysmian is a public company, with history going back to 1879, and €12bn of revenues in 2021. It is headquartered in Milan, with 29,000 employees, operating 108 cabling solutions plants in 50 countries. But can we find a Prysmian power cable technology ‘moat’, or de-risk future project delivery by reviewing Prysmian’s recent patents?

We are increasingly excited by an up-cycle in power transmission, associated with the build-out of renewables. To this end, 75% of Prysmian’s business is energy (50% is power-infrastructure, 22% is industrial and network solutions, 13% project work, 12% telecoms). The company has inter-connected 35 large wind farms in the past decade and run 30 inter-connectors.

After reviewing recent patent filings, we conclude that Prysmian has developed a partial moat across multiple, incremental improvements and specializations in cabling solutions, and its R&D has likely also lowered future installation risks on lump-sum turnkey contracts.

Large power cables are challenging, because current flows generate heat via the Joule effect. Power cables must not heat up above 90C, or it can cause safety issues and damage to materials. Another challenge for cables is water-proofing, especially in deep water, as any water that penetrates the cable could flash to steam, cause damage, and corrode the conducting metals. Another challenge is installing cables without damaging them, in non-accessible spaces or deep water, which is achieved by wrapping metallic armor around the cables, although this increases weight. A 400kV cable can weigh 40kg/meter.

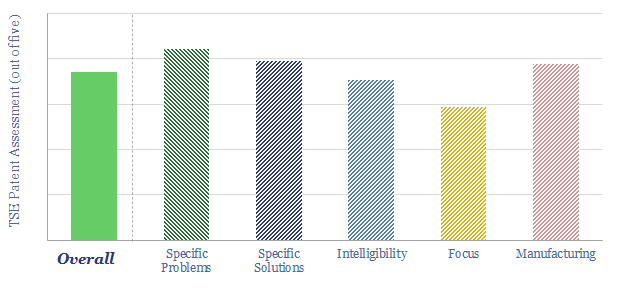

Against this backdrop, Prysmian scores well on our usual patent assessment framework, with specific, clear, intelligible and manufacturing-focused patent filings; and many interesting technical disclosures around its optical and power cabling solutions: from real-simplified testing while installing ultra-deepwater HVDCs to cooling EV fast-charging cables. Full details on Prysmian power cable technology are in the data-file.