This technology review gives an overview of PureCycle Technologies, founded in 2015, headquartered in Ohio/Florida, USA, went public via SPAC in 2021 and currently has c150 employees. The company aims to recycle waste polypropylene into virgin-like polypropylene, preventing plastic waste, while saving 79% of the input energy and 35% of the input CO2 compared with virgin product.

Why is this challenging? Even after sorting and washing, plastic waste is still contaminated with spoiled food, chemicals, dyes and pigments, resulting in recycled product being dark and low-quality. Several other patents have sought to address these issues, but with only varying success, and via complex and/or costly methods.

Controversies have been raised by a critical report from a short-selling firm. However, our usual patent review allowed us to infer how the process is envisaged to work, including good, specific and intelligible details, covering the solvents, filtration methods, medium temperatures and medium-high pressures (data here). This de-risks some of the risks.

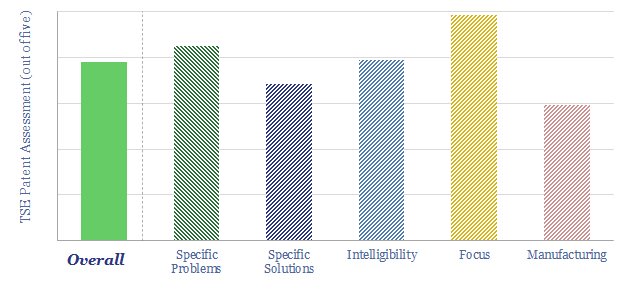

This note contains our observations from our PureCycle technology review, the company’s ambitions, challenges, and scores the patent library on our usual dimensions of problem specificity, solution specificity, intelligibility, focus and manufacturing readiness. We also tabulated technical data that is presented in several patents.

Further research. Our recent commentary on PureCycle technology is linked here.