Servo motors form a $16bn pa market, used in robotics, precision manufacturing equipment, CNC machines, aerospace and med-tech. This data-file estimates servo motor costs, based on underlying controller costs, motor costs and reduction gear costs. Hence we have attempted a simple servo motor cost calculator.

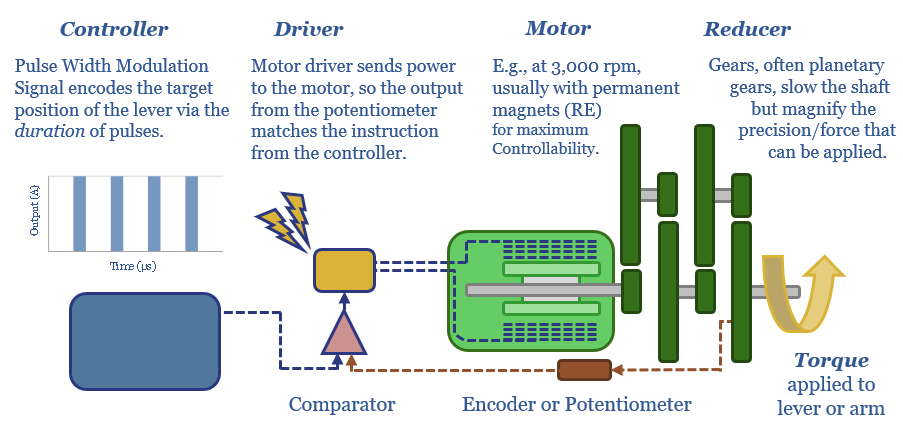

The characteristic goal of a servo-motor is to precisely control the position of a lever or arm.

This is achieved by pulse-width modulation from MOSFETs in a controller, driving a motor, which in turn is connected to a series of reduction gears amplifying the torque and precision, and then feeding back to the motor to indicate whether the lever/arm has reached the intended position (schematic below).

Usually, when estimating the costs of prime movers, it makes sense to measure costs in $/kW. These statistics are compiled in the data-file, but really it makes more sense to capture the costs of servos per Nm of load that can be controlled.

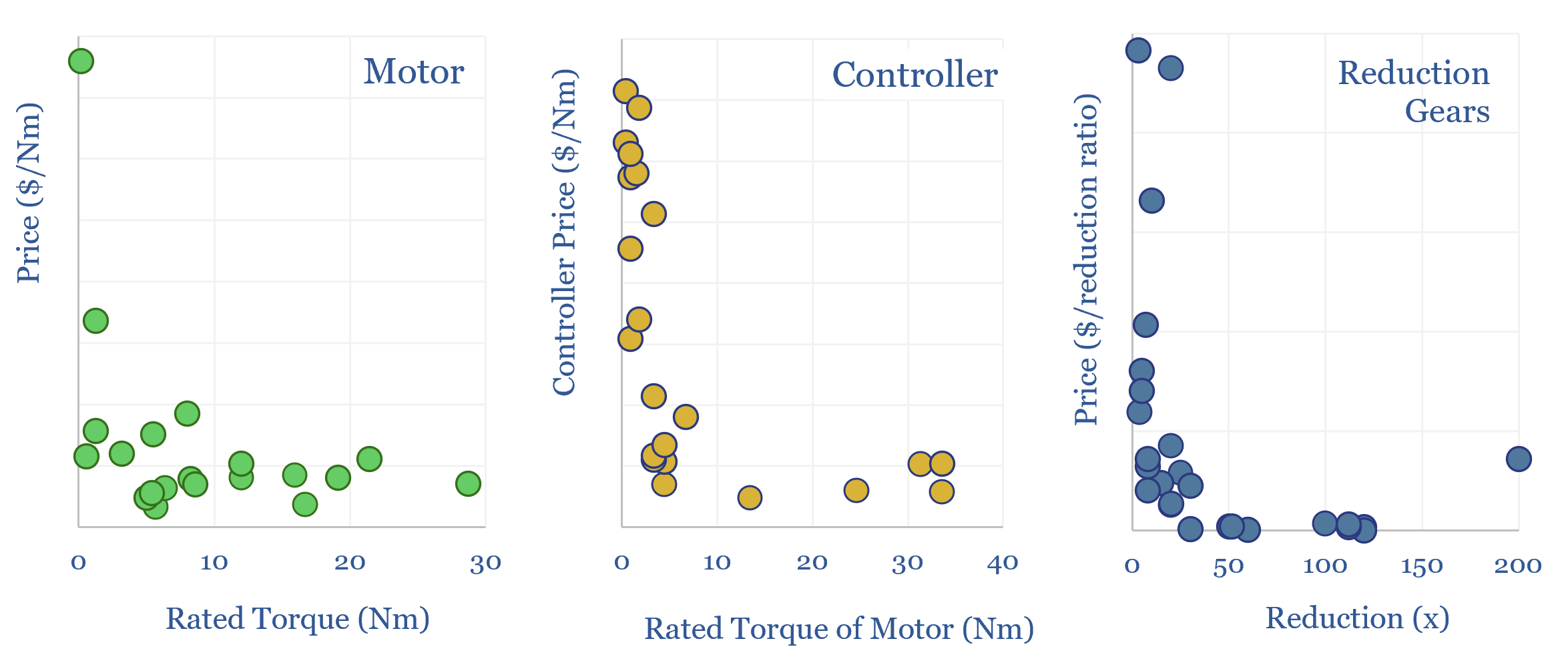

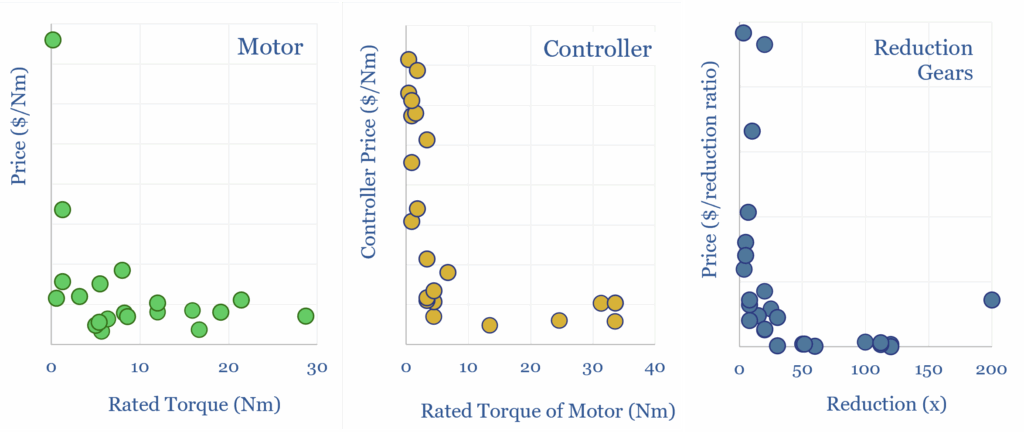

The costs of servo motors and the costs of their controllers decay as a function of the motor’s rated torque. The costs of reduction gears also decay according to the reduction ratio of the gears.

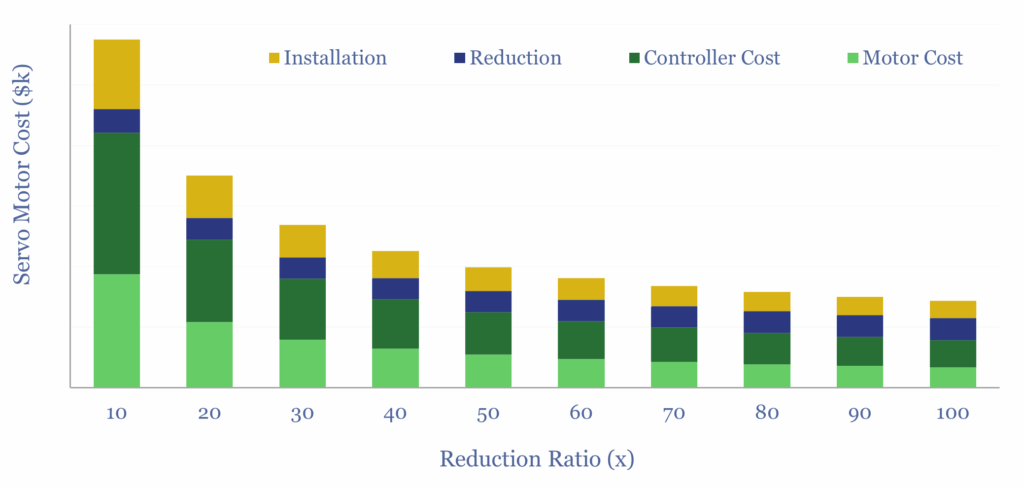

Good rules of thumb might be that a controller costs $200/Nm, the motor costs $200/Nm and the reducers cost $20/reduction. All else equal, this will warrant building systems with larger reducers, in order to slim-line the costs of the motors and controllers, for the same output torque.

Hence the large servo motor in a robot arm capable of lifting 100kg at a distance of 1m, might cost over $10k, of which c30% is the controller, 30% is the motor, 20% is the reduction gears and 20% is the wiring/hook-up of the system.

A smaller and lower-end servo motor might cost in the range of $100-1,000 when fully installed. But it really does depend on the precision and quality of the device. Servo motor costs can be stress-tested in the data-file.

Larger servo motors are invariably more efficient. For example, the parasitic load from the controller ranges from 0.2% of the output load, at the largest servos, to over 20% at the smallest ones.

Leading companies in servo motors, controllers and reduction gears are profiled in the data-file. All of the underlying data in our cost build-up are taken from cost quotes on specific products, from these specific producers. In particular, the data-file ended up capturing data-points into SIMOTIC servo motors from Siemens and servo motors from Yaskawa.