Production optimisation can uplift mature fields’ output by 5-20%, varying production rates, chokes, pump-rates and EOR strategies, well-by-well across a field. It’s another way to stave off decline rates. But how?

This data-file summarises the methodology employed by BP, based on the most detailed patent we have seen on the topic, in our screen of 3,000 patents across the industry. BP is a leader in this area. Having digitised most of its operated assets, production optimisation comes next.

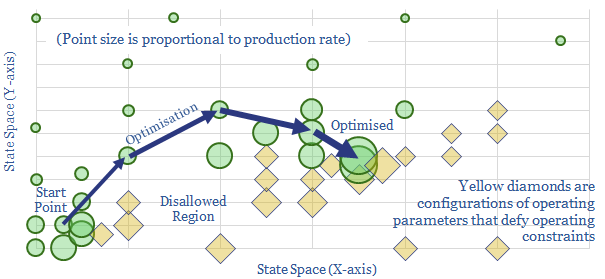

The typical challenge across the industry, is that as many as 20-30 changes may be required to optimise a large field, which is time-intensive for engineers to perform manually, hard-to-prioritise, hard-to-sequence and prone to errors that might defy operational constraints on individual wells.

BP’s system iterates through potential changes, selects the most promising candidates, validates that they comply with operating constraints, and shifts production to an optimal state (chart above).

This data-file includes our summary of BP’s patent, schematics for its implementation, data behind our chart above and a ranking of BP’s “digital technology” versus other Majors that we have assessed.