Search results for: “gas”

-

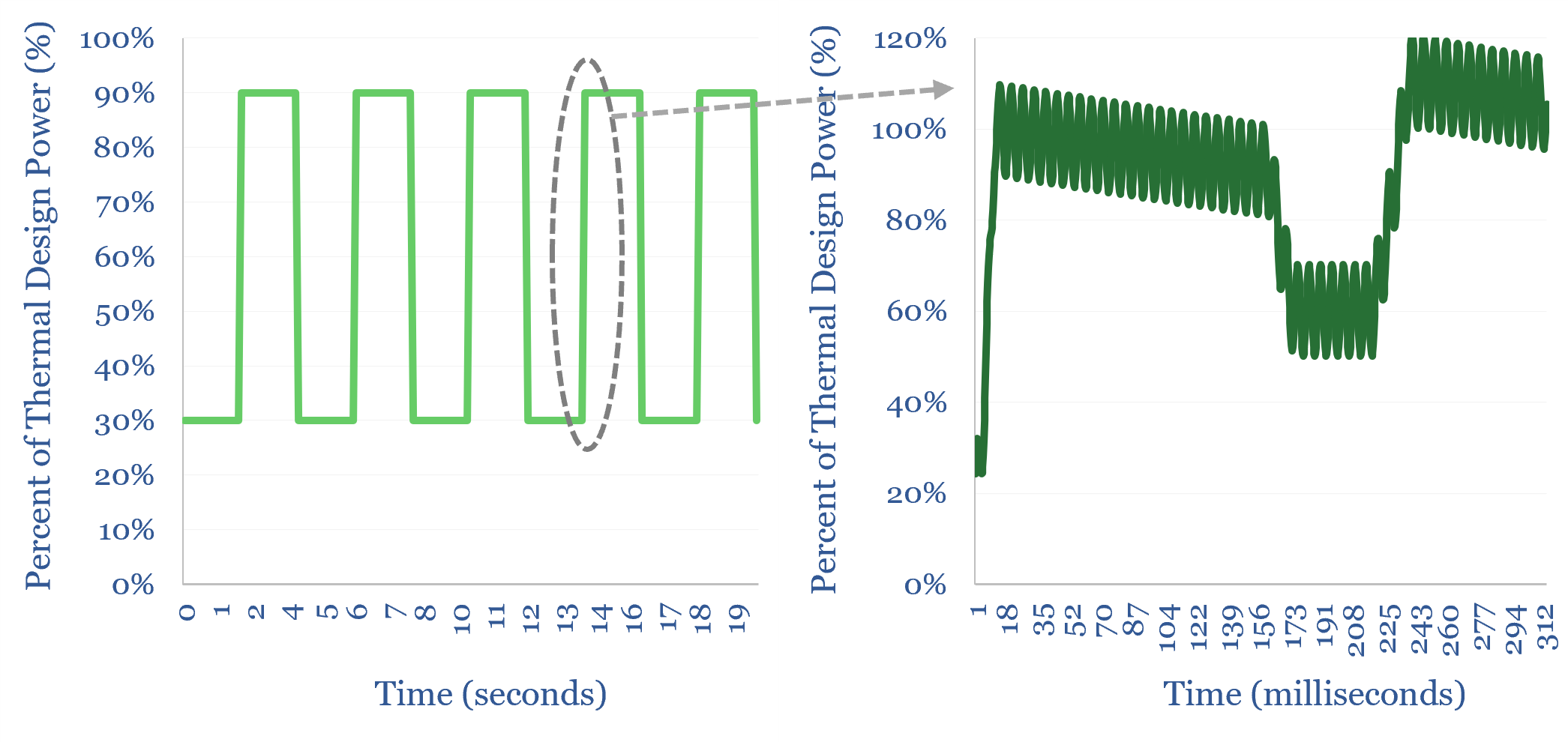

Data center energy: caps lock?

Everybody knows “AI data centers use round-the-clock power”. Yet one of the biggest power challenges for AI data data centers is precisely that they do not use round-the-clock power. They incur large load transients that cannot be handled by batteries, power grids or most generation. This 15-page report explores data center load profiles, which may…

-

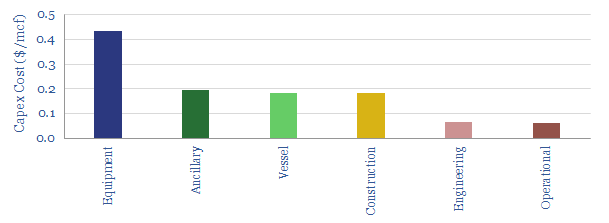

Floating LNG: do the costs work?

A 2.5MTpa Floating LNG vessel using the Golar/PRICO process would cost c$700/tpa, or $1.1/mcfe. A $2.5/mcf liquefaction-spread is therefore needed for a 10% return. The key economic risk is ‘uptime’. This file contains our workings; including cost-estimates across 17-categories, such as compressors, heat-exchangers, vessel-costs, et al.

-

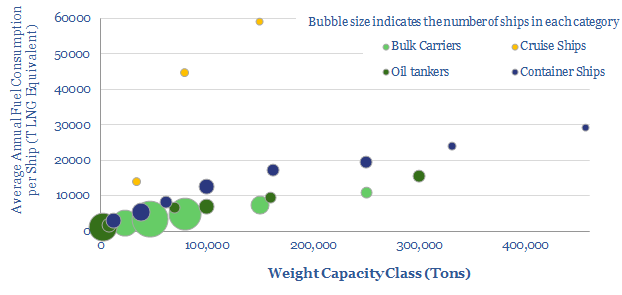

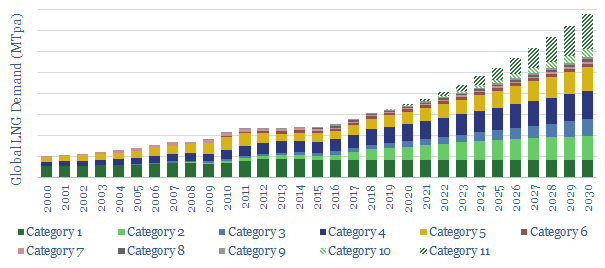

Global shipping and the switch from fuel oil?

The 240MTpa shipping-fuels market will be disrupted from 2020, under IMO sulphur regulations. Hence, this data-file breaks down the world’s 100,000-vessel shipping fleet into 13 distinct categories. We see 40-60MTpa upside to LNG demand from 2040.

-

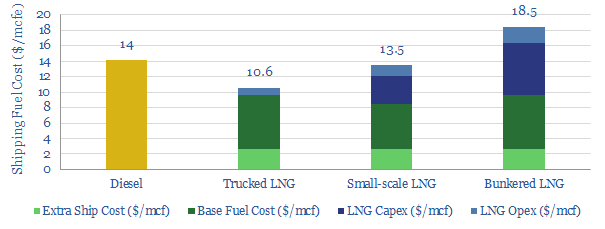

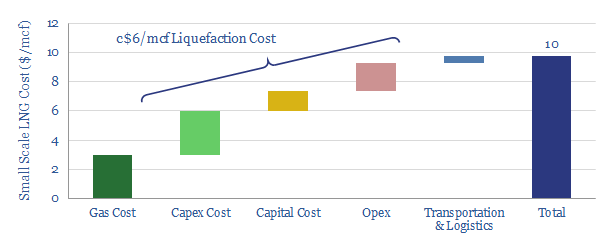

LNG as a Shipping Fuel: the Economics

This data-file provides line-by-line cost estimates for LNG as a shipping fuel, for trucked LNG, small-scale LNG and bunkered LNG. After IMO 2020 regulations buoy diesel pricing, it should be economical to fuel newbuild ships with small-scale LNG; and in the US it should be economical to convert pre-existing ships to LNG.

-

LNG in transport: scaling up by scaling down?

Next-generation technology in small-scale LNG has potential to reshape the global shipping-fuels industry. Especially after IMO 2020 sulphur regulations, LNG should compete with diesel. This note outlines the technologies, economics and opportunities for LNG as a transport fuel.

-

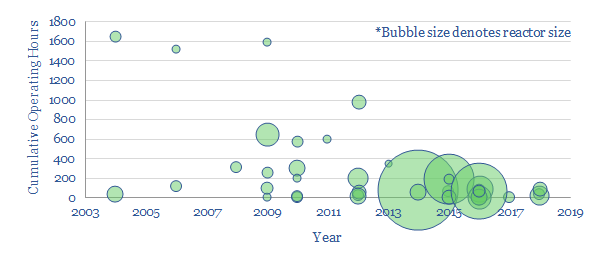

Chemical Looping Progress?

Chemical Looping Combustion could clean up future coal or gas-fired power. But will it work? We have tabulated data from the technical literature on 40 chemical looping combustion pilots. They have run collectively for 10,000 hours. They promise 38% energy efficiencies for zero carbon emissions.

-

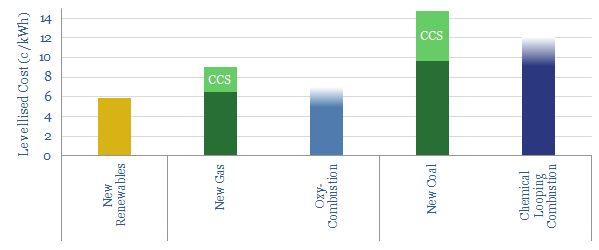

De-carbonising carbon?

Decarbonisation is often taken to mean the end of fossil fuels. More feasible is to de-carbonise fossil fuels. This 15-page note explores two top opportunities for low-cost decarbonisation of coal and gas: ‘Oxy-Combustion’ and ‘Chemical Looping Combustion’. Leading Oil Majors support these solutions.

-

Long-Term LNG Demand: technology-led?

This is a simple model of long-term LNG demand, extrapolating out sensible estimates for the world’s leading LNG-consumers. On top of this, we overlay the upside from two nascent technology areas, which could add 200MTpa of potential upside to the market. Backup workings are included.

-

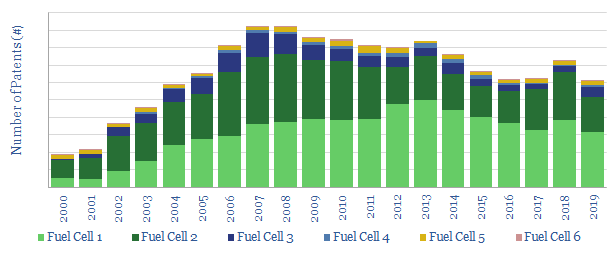

Fuel Cell Patents: twenty years of progress?

This data-file tabulates the numbers of patents filed into different types of fuel-cells, from 2000-2020, globally and in key geographies: China, Japan, Korea and the US. Research activity peaked in 2008 and has since fallen by 30%. Japanese research has collapsed, while China’s has ascended.

-

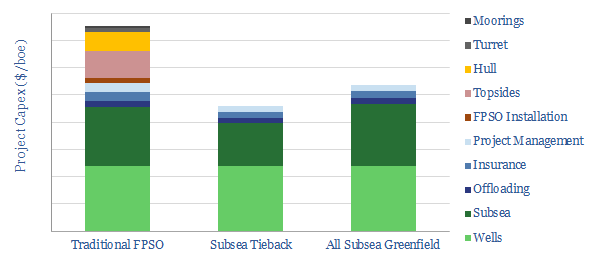

Floating production systems versus subsea tiebacks: the costs?

This model estimates the line-by-line costs of an FPSO project, across c45 distinct cost lines (in $M and $/boe). We estimate c$750M of cost savings for a tieback, and c$500M of cost savings for a fully subsea development, as compared against a traditional project with a traditional production facility.

Content by Category

- Batteries (89)

- Biofuels (44)

- Carbon Intensity (49)

- CCS (63)

- CO2 Removals (9)

- Coal (38)

- Company Diligence (95)

- Data Models (840)

- Decarbonization (160)

- Demand (110)

- Digital (60)

- Downstream (44)

- Economic Model (205)

- Energy Efficiency (75)

- Hydrogen (63)

- Industry Data (279)

- LNG (48)

- Materials (82)

- Metals (80)

- Midstream (43)

- Natural Gas (149)

- Nature (76)

- Nuclear (23)

- Oil (164)

- Patents (38)

- Plastics (44)

- Power Grids (130)

- Renewables (149)

- Screen (117)

- Semiconductors (32)

- Shale (51)

- Solar (68)

- Supply-Demand (45)

- Vehicles (90)

- Wind (44)

- Written Research (354)