Completing a shale well depends on over 40 variables. Each one can be optimised using data. It follows that next-generation data will deliver next-generation shale productivity. Hence our new, 25-page note focuses on the most exciting new data methodology we have seen across the shale space: distributed acoustic sensing (DAS) using fiber-optic cables. It has now reached critical momentum, to transform the shale industry in six main ways…

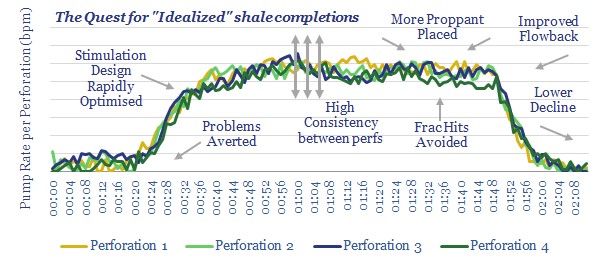

(1) Productivity gains. DAS advances the shale industry’s quest for ‘ideal’ completions (chart above). The best studies to-date have already achieved c25% production uplifts and c10% cost-savings. Pages 2-14 describe the technology, its maturation and the recent step-change for its application in shale.

(2) Further DAS improvements could deliver further productivity gains throughout the 2020s, materially lowering the long-term decline rates in shale basins (see page 17).

(3) Economics break even at $15/bbl when deploying DAS in a cross-well, adding $0.8M of NPV10 at ($40/bbl oil) (see page 18).

(4) DAS levels the playing field, allowing newer basins and smaller operators to derive competitive designs quickly. Without this ability large operators in the Permian will crowd out the rest (see pages 15-16).

(5) DAS disrupts the Services industry, gaining dominance over other diagnostic techniques, such as seismic. Services’ adaptability is screened (see pages 20-21)

(6) DAS will give E&Ps and Majors an edge. To help quantify who is in the lead, we identify and rank the “Top Dozen” operators’ progress, based on their patents and technical papers (see pages 22-24) .