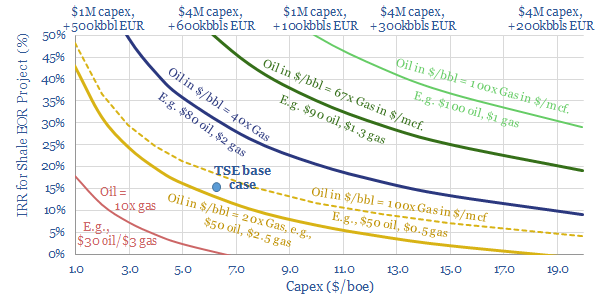

We see enormous opportunity from CO2-EOR in the Permian. It can double well productivity, generate 15-20% IRRs (at $50 oil) and uplift production potential from the basin by 2.5Mbpd. The mechanism and economics are covered in detail in our deep-dive note, Shale-EOR, Container Class.

But what is happening at the leading edge, as companies try to seize the opportunity?

To deploy CO2-EOR, operators must be confident in the technology. It must be predictable, with well-calibrated models informed by field-tests and laboratory studies.

Excitingly, Occidental Petroleum is developing such models. Its laboratory analysis into CO2-EOR has been published in a new SPE paper, in partnership with CoreLabs.

Oxy is at the forefront of CO2-EOR, according to our screening of patents and technical papers. It has conducted 4 x field trials, with further ambitions to lower decline rates from 2020 and drive value through its Anadarko acquisition.

This note profiles our top five findings from Oxy’s recent technical paper. CO2-EOR’s deployment is supported.

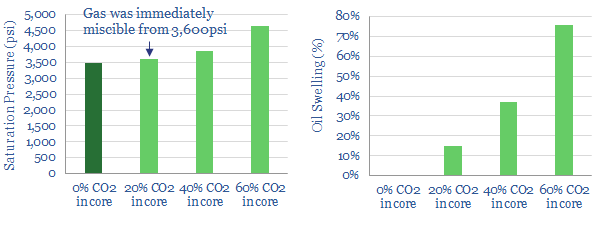

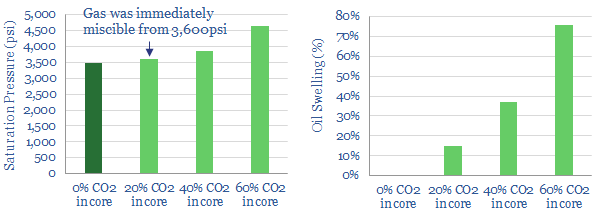

(1) CO2 was found to be “the best solvent” for huff’n’puff in the Permian, after laboratory-testing Wolfcamp cores, with CO2, methane and field gas. Under simulated reservoir conditions, around 3,600psi, bubbles of CO2 immediately began dissolving into the oil, helping to mobilise it.

(2) CO2 swelled the oil by 15-76% under the reservoir conditions tested in the study (below, right). Swollen oil is more likely to dissociate from the reservoir rock and flow into the well.

(3) Accurate ‘Equation of State’ models have been developed, matching the pressure, viscosity and well data from the laboratory study.

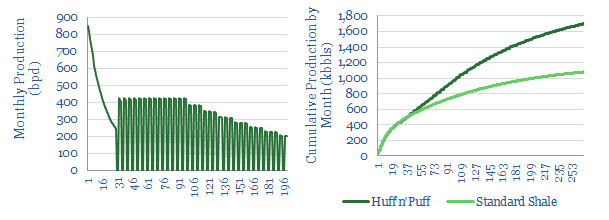

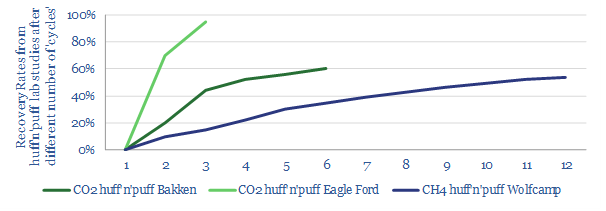

(4) Multiple Cycles. Huff’n’puff works by sequentially ‘huffing’ gas into a depleted shale well to entrain residual oil, then ‘puffing’ back the mixture of gas and oil. Ideally, this cycle can be repeated multiple times, recovering more oil each time (illustration below). Oxy’s laboratory study continued recovering material volumes of oil over six cycles. Lighter fractions were recovered in earlier cycles, followed by heavier fractions in later cycles. The authors concluded: “The multi-cycle incremental recovery – even at the small core plug scale – suggests the significant potential for multiple HnP EOR cycles for a future unconventional EOR project design”.

(5) Huge Recovery Factors. What slowed the eventual recovery of oil in the study was the high volume of oil already recovered. Initially, these shale samples contained 10.3% oil (as a percentage of the initial pore volume). By the end of the huff’n’puff trial, they contained just 2.4%, implying c77% of the oil had been drained: an incredibly high number, when compared with c 8-10% recovery factors in most analyst models. The result matches other lab tests we have seen in the technical literature (chart below). The field-scale implications of these studies are discussed in our deep-dive research.

Source: Liu, S., Sahni, V., Tan, J., Beckett, D. & Vo, T. (2019). Laboratory Investigation of EOR Techniques for Organic Rich Shales in the Permian Basin. SPE.