Electro-fuels are hydrocarbons produced primarily from renewable power, CO2 and water. They are reminiscent of the adage that ‘the fastest way to become a millionaire is to start out as a billionaire then found an airline’. Because all you need for 1boe of these zero-carbon fuels is 2-3 boe of practically free renewable energy. Abatement cost is $1,000/ton. At best this could deflate to $150/ton. An ambitious new industry is forging ahead. The opportunity and challenges are explored in this 19-page report.

There are three excellent reasons for wanting to commercialize electro-fuels, converting renewable electricity, CO2 and water into zero carbon fuels. They are spelled out on pages 2-4.

Renewable power is the first ingredient needed to produce electro-fuels. We outline how much power, and at what cost, on pages 5-6.

A carbon source is the second ingredient needed. We have created a CO2-sourcing cost curve, then modelled a CO2 electrolysis stack, on pages 7-9.

A hydrogen source is the third ingredient needed. Our assessment of hydrogen costs is re-capped on page 10.

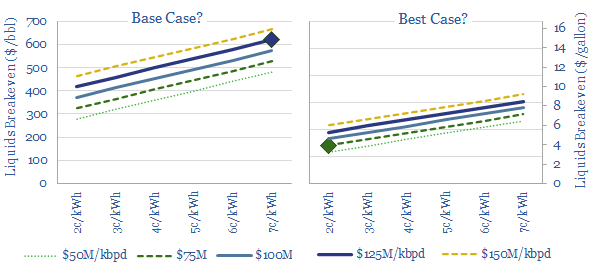

Re-combining these building blocks into an electro-fuel will most likely follow one of three main pathways: Fischer-Tropsch, green methanol and/or alcohol-dehydration. We spell out each option, and its ultimate cost on pages 11-14.

Our best case scenario is refined on page 15-16. Because we have broken down the costs of electro-fuels into their component parts, we can assess what is required for a c$150/bbl or c$150/ton abatement cost, and is this realistic?

Leading companies are profiled on pages 17-19. We screened 15 companies in the space. Many are forging ahead with pilot projects, or developing superior technologies.