CO2 has unusual physical properties, which make small-scale liquefaction and transport much more viable than we had expected. The energy burden is 70% less than other industrial gases. Total CCS costs are $50-90/ton for leading examples. This 15-page note outlines the opportunity.

Liquefying CO2 may allow smaller industrial facilities to capture and transport their CO2 to disposal sites, where permitting a pipeline is not feasible or economical. This expands the opportunity for CCS. Early proposals to do this are explored on pages 2-4.

The physics are helpful and are explained on pages 6-8. CO2’s unusual triple point means that the energy costs of CO2 liquefaction are around two-thirds lower than the heavy-duty cryogenics that are already used to liquefy almost 1GTpa of industrial gases globally.

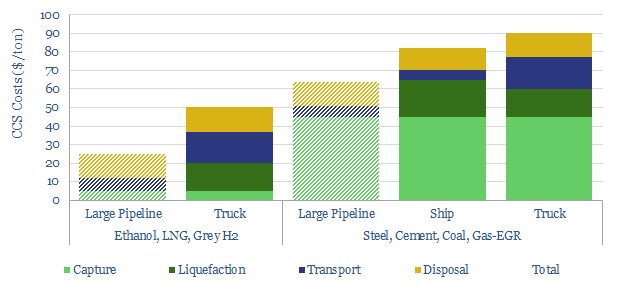

The economics of CO2 liquefaction and transportation are laid out on pages 9-12. We have modeled a separate liquefaction plant, a convoy of CO2-carrying trucks, and larger liquid CO2-carrying ships. Including capex, energy and CO2 costs.

The main operational hurdles are described on page 13. We have reflected additional safety measures and staff training costs in our models as a consequence.

Who benefits? The opportunity is summarized on pages 14-15. The most ambitious project to-date will see Aemetis capture around 2MTpa of CO2 for disposal in California’s Central Valley, where the LCFS could yield $250/ton revenues.