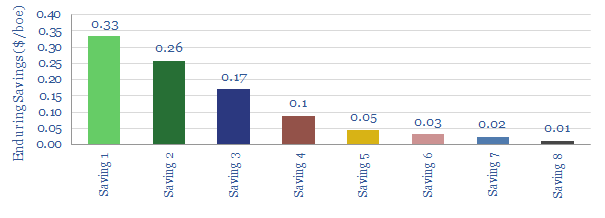

A typical offshore operator can very readily save $1/boe via continued, digital deflation; which is tantamount to $1bn per annum at a c3Mboed Oil Major.

Our numbers are derived from a case study by Cognite, which is among the leaders in oilfield digitization, collaborating with cutting-edge E&Ps, as described below.

Digitization remains the most promising opportunity to improve offshore economics. But the gains are granular and can only be seen by delving into the detail…

[restrict]

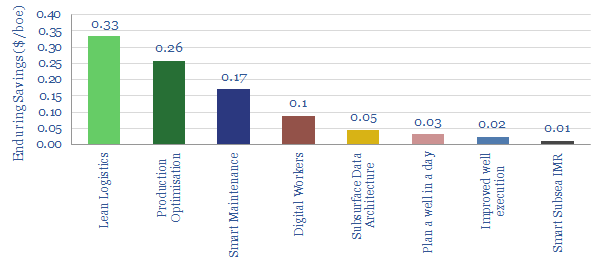

This short note will focus further upon three particular avenues for digital deflation, which collectively account for $0.6/boe of cost savings at a typical offshore operator.

All are achieved using greater data instrumentation, as highlighted in Cognite’s recent case study, based on working alongside Aker-BP, which we calculate can save $1/boe across the operator’s portfolio (chart below).

(1). Production Optimisation can be attained by increasing the throughputs in processing units, such as separators. In Cognite’s example, this is safely achieved by using better data from multi-phase flow-meters upstream of the processing units. Better data enables better performance. Deferrals associated with the flow-meter calibration are also reduced by 30-50%.

(2). Smart maintenance of equipment can be achieved by greater monitoring. For instance, the Ivar Aasen sends data back to shore, in real time, on 90,000 information packages, including 18,000 valves, all the wells, compressors, pumps and generators. Cognite’s example is at these shut-down valves and fire dampers, which now require 80% fewer maintenance hours to check. In addition, the number of hours per miantenance check is reduced by 90%.

(3). Improved information flow to “digital workers” improves productivity. As context, maintenance of a large process unit (e.g., a 1st stage separator) may require 1,300 planning hours per year, but this can be improved using data (video below). In turn, this superior planning reduced the time spent on routine inspections by c50%, increasing the number of monthly maintenance jobs by 10% and with better HSE performance.

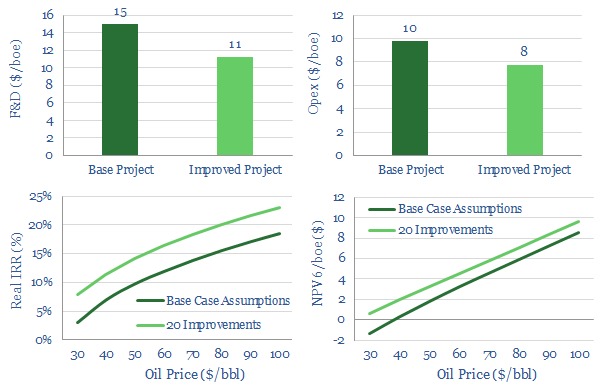

Digital improvements offer great potential to improve offshore economics. However, as we have highlighted, no individual improvement is a magic bullet. Uplifting IRRs, particularly on new greenfield projects by say, 5pp, requires progress on as many as twenty different dimensions (chart below).

This is where Thunder Said Energy can help, screening the economic opportunities and best-practices across different companies, using our databases of patents and technical papers.

[/restrict]