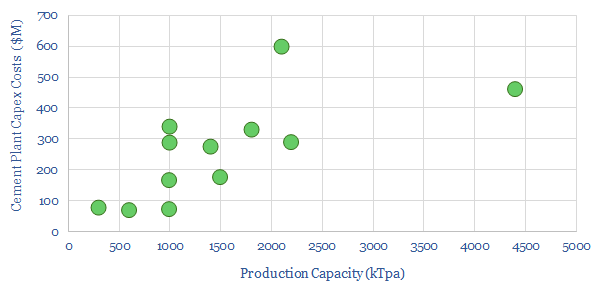

This data-file captures cement costs, based on inputs, capex and energy economics. A typical cement plant requires a cement price of $130/ton for a 10% IRR, on capex costs of $200/Tpa, energy intensity of 1,000 kWh/ton and CO2 intensity of 0.9 tons/ton. Cement costs can be stress tested in the data-file.

The world produces 4GTpa of cement, which is blended with aggregates to yield 30GTpa of concrete in the construction industry; some of the most extensively produced materials in industrial civilization.

Cement is also important for the energy transition. A wind turbine uses 67 tons of cement per MW. So too might foundations of utility scale solar, power transmission lines, or the “pads” used to house batteries and hydrogen plants.

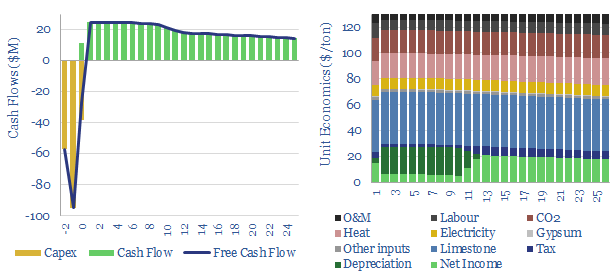

The marginal cost of cement production is estimated at $130/ton in this data-file, in order to achieve a 10% IRR, which is similar to the average price of cement in the US in 2021-22.

The breakdown of costs, in USD per ton of cement, includes: $40/ton for limestone inputs which are then calcined into clinker; $20/ton for heat which is mainly coal and petcoke today; $20/ton in capital costs for a 10% IRR; $20/ton for CO2 and the CO2 price can be flexed in the model; $10/ton for electricity; and $20/ton for other material inputs, labor, O&M and taxes.

CO2 intensity is estimated at 0.9 tons/ton in our base case, but there are interesting opportunities for decarbonization. Half of the CO2 from a cement plant is 20-30% concentrated CO2 from the thermal decomposition of limestone (CaCO3->CaO + CO2) which could be amenable to CCS.

Switching out solid fuels (coal) for gas would save 0.1 tons/ton. Around 100kWh/ton of electricity use is the grinding of inputs and clinker, and this is a very flexible load that can easy “demand shift” to run off a heavy share of renewables in future power grids.

Inflation in cement costs could be a challenge in the energy transition. European heat, electricity and CO2 prices can very easily double the marginal costs of production. Much of the growth in cement demand is also concentrated in emerging world countries, where cost sensitivity is high and CO2 is lower down the priority list.

We have also screened technologies aimed at decarbonizing cement and concrete, such as Solidia, CarbonCure, or thinking laterally, substitution towards timber products.