CO2-cured concrete has c60% lower emissions than traditional concrete, which is the most widely used construction material on the planet, comprising 4bn tons of annual CO2 emissions, or 8% of the global total. This data-file assesses Solidia CO2-cured concrete.

This data-file profiles Solidia’s industry-redefining product — CO2-cured cement — based on an impressive array of 38 patents. We model the production costs, CO2 costs and full-cycle economics; then size the addressable market and outline our notes and patent data.

A rapid scale-up is now underway. We see realistic medium-term CO2 savings of 10MTpa in the US and 300MTpa globally.

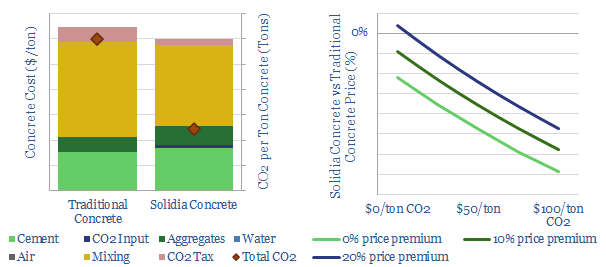

A CO2 price would further enable cost-competitive pricing, even after earning a 10-20% pricing premium versus traditional concrete, yielding exceptional IRRs.

An interesting side-note is that producing cement is not particularly CO2 intensive. Around 1 ton of CO2 is usually emitted per ton of cement. This translates into around 0.12 tons of CO2 per ton of concrete. However, the issue is that these construction materials are produced in massive quantities: around 4 GTpa of cement and around 35 GTpa of concrete. These are huge numbers and contextualized further in our breakdown of global CO2 emissions.

To read more about Solidia CO2-cured concrete and its economics, please see the article sent out to our distribution list.