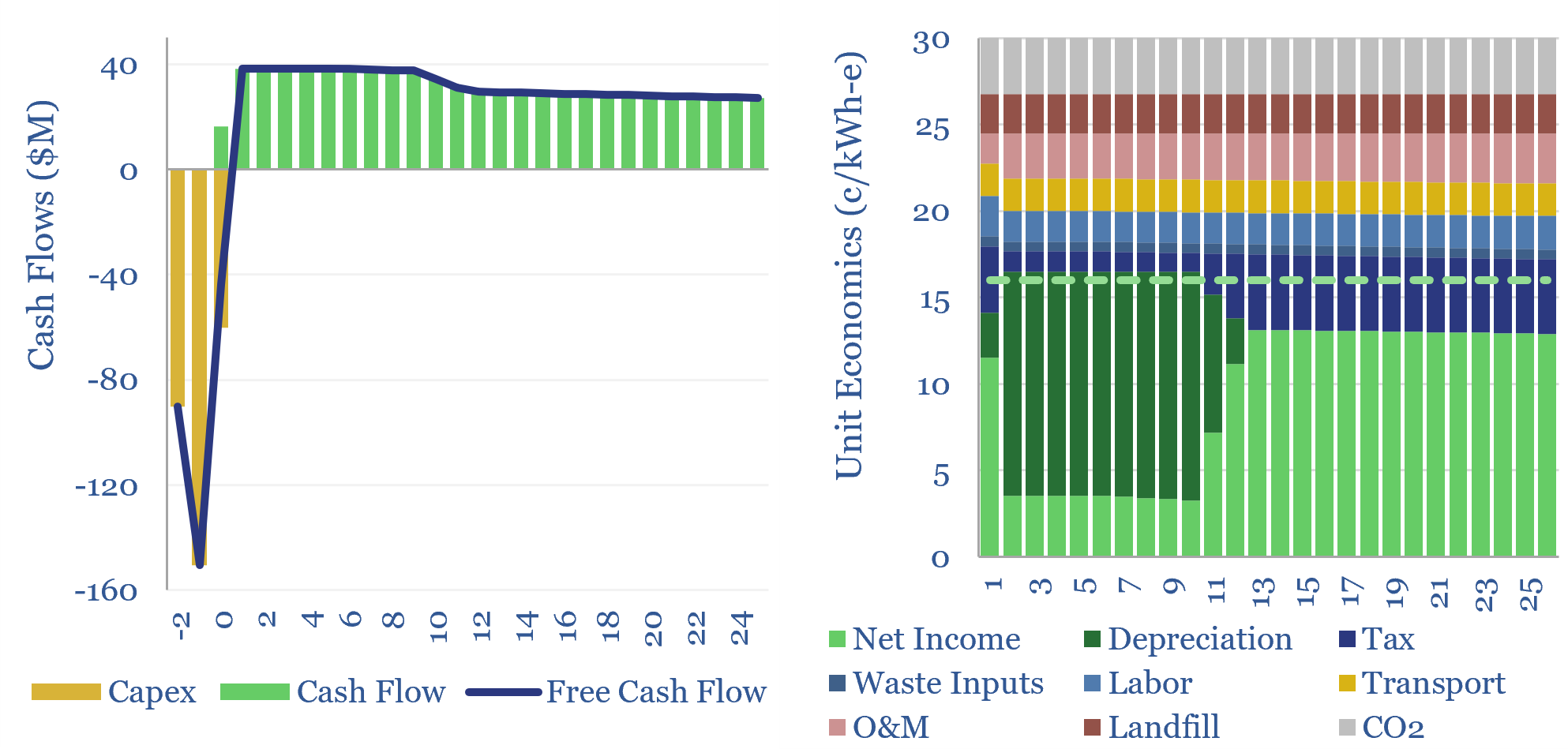

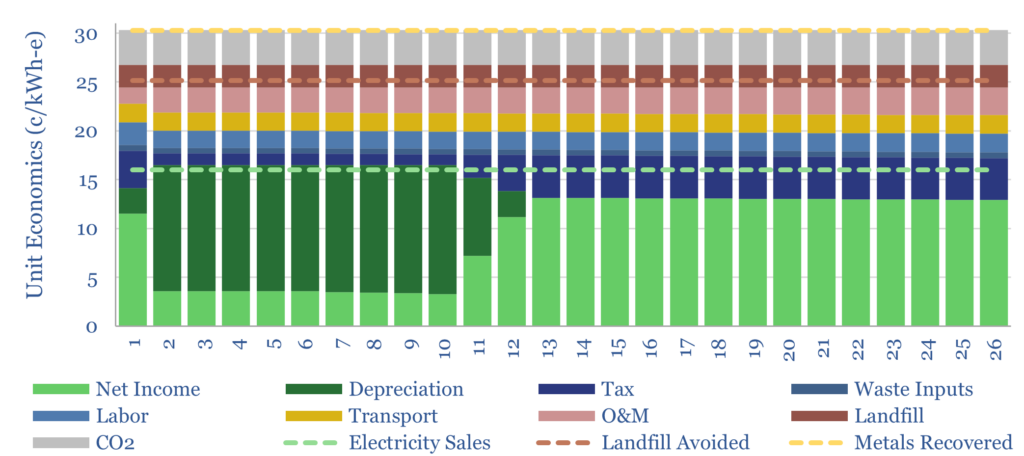

A typical waste-to-energy plant, without subsidies, must charge 16c/kWh to generate a 10% IRR off of c$7,000/kW in capex costs, plus another 14c/kwh-equivalent of revenues from avoided landfilling and metals recovery. This economic model covers waste-to-energy levelized costs of electricity.

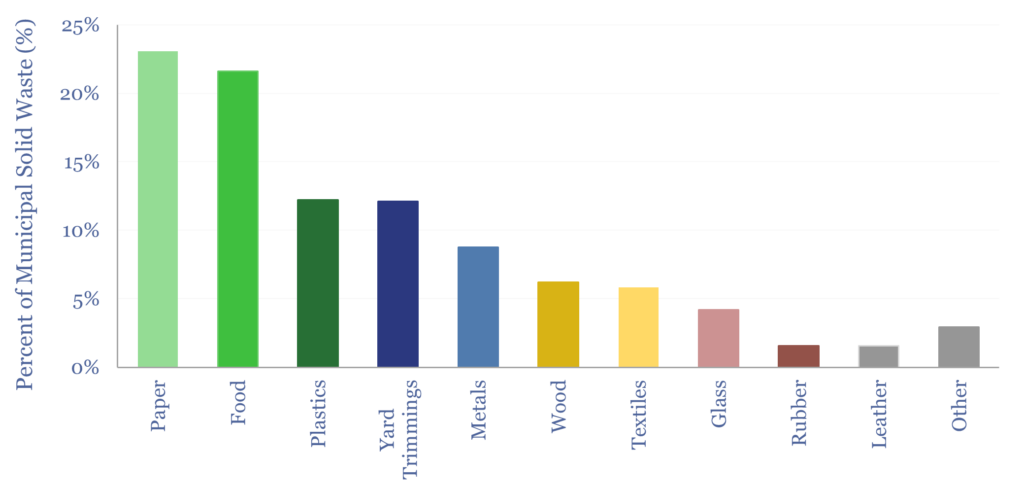

The world generates 2GTpa of municipal solid waste, which in turn could support around 1,250 TWH of electricity generation if its combustible components (chart below from the EIA) were shredded, incinerated and the resultant heat was used to generate steam, which in turn could drive a turbine and generator.

Today, IRENA estimates that about 100 TWH of electricity is generated from 2,500 Renewable Municipal Solid Waste plants globally, with 20GW of combined capacity. Over half of this total is in China.

This data-file captures waste-to-energy costs. These plants require a 16c/kWh electricity price to generate a 10% IRR off of c$7,000/kW of capex, typically. In turn, this assumes c60% utilization, and another 14c/kWh of effective revenues from landfill avoidance and metals recovery, for 30c/kWh of total effective revenues.

Specifically, landfill avoidance can be considered as an effective revenue source, as landfill fees/tipping fees now surpass $70/ton in many countries, while MSW has 90% lower volume and 75% lower mass after combustion. Combusted material is also inerted and does not produce methane in landfills.

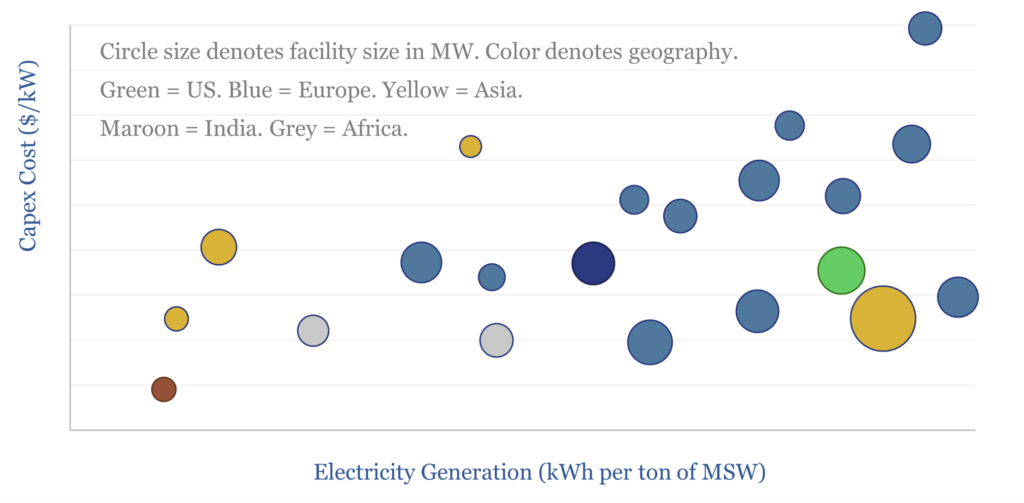

Capex costs of waste-to-energy plants are high because of the need to scrub nasties out of post-combustion gases. Especially when unrecyclable plastics are combusted, or other synthetic materials, there can be high quantities of fly ash and even dioxins from halides. For example an electrostatic precipitator tends to cost $50-100/kW and we also expect there are several other scrubbers and water wash units cleaning up exhaust gases. Capex costs also vary with efficiency. Capex costs and efficiency levels of past projects are tabulated in the data-file.

The CO2 credentials of waste-to-energy facilities are debatable. Advocates argue that these facilities avoid methane emissions from landfills. Critics argue that effectively they are burning unrecyclable plastics, with low net efficiency, and thus CO2 intensity factors can be 2x higher than generating electricity from CCGTs or even the average grid.

The technology is best-suited to regions with high wholesale energy prices, high landfill taxes, and where population densities are particularly high (minimizing the costs of gathering and transporting waste material).

Please download the data-file to stress-test waste-to-energy levelized costs and returns. Variables that can be varied include MSW cost, metal recovery rates and prices, capex costs in $/kW, utilization rates in %, net generation efficiency in %, burn down rates, and other opex cost lines such as O&M and labor rates.