Electrostatic precipitator costs can add 0.5 c/kWh onto coal or biomass-fired electricity prices, in order to remove over 99% of the dusts and particulates from exhaust gases. Electrostatic precipitators cost $50/kWe of up-front capex to install. Energy penalties average 0.2%. These systems are also important upstream of CCS plants.

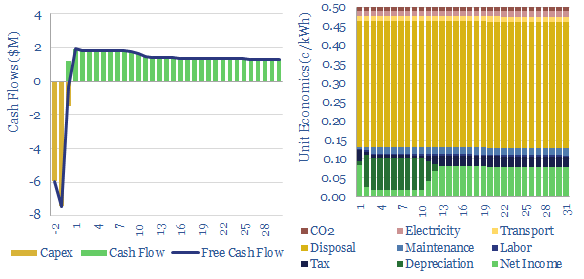

This data-file captures electrostatic precipitator costs, in order to remove particulate dusts from exhaust gases, especially in coal-fired power plant applications. As usual, we model what power plant increment is required to earn a 10% IRR on the up-front capex, opex and other costs of an air pollution control installation.

What is an electrostatic precipitator? ESPs flow exhaust gases through a honeycomb of tubes. Each tube contains a high-voltage wire, creating an electrical corona, imparting a charge to passing dust particles. The charged dust particles will then be attracted towards collecting plates, from which the dust can later be collected via rapping the plates (dry precipitators) or spraying the plates (wet precipitators).

Our base case cost estimate is that an electrostatic precipitator can add 0.5 c/kWh to the costs of a coal-fired power plant, to earn a 10% IRR on an ESP costing $50/kW, and incurring a 0.2% total energy penalty.

However, two-thirds of our cost build-up reflects subsequent disposal of captured dusts and particulates, especially where these dusts contain heavy metals. Not all facilities will incur these costs. Landfill costs vary by region. Trucking costs depend on distance. And different coals have different contaminants. Thus disposal costs can be flexed in the model.

The Electrostatic Precipitator market is approaching c$10bn per annum. It is increasingly important in the energy transition, as exhaust gases require large amounts of clean-up upstream of post-combustion CCS plants, to prevent releases of amines or their breakdown products, which can be problematic for air permitting and air quality. Also important for CCS stability are flue gas desulfurization (remove SO2) and selective catalytic reduction (remove NOXs).

Leading companies in electrostatic precipitators are briefly discussed on the ‘notes’ tab. The market includes industrial giants (Mitsubishi, GE, Siemens Energy, Alstom) through to more specialized companies that have historically installed over 5,000 air pollution control systems worldwide (Babcock, FLSmidth, Ducon, Wood Group).