This data-file captures selective catalytic reduction costs to remove NOx from the exhaust gas of combustion boilers and burners. Our base case estimate is 0.25 c/kWh at a combined cycle gas plant, which equates to $4,000/ton of NOx removed. Capex costs, operating costs, coal plants and marine fuels can be stress-tested in the model.

NOx pollution, mainly NO, is formed during combustion of fuels, when temperatures exceed 1,200ºC, and nitrogen gas in the air can oxidize. This matters as NOx gases are precursors to PM2.5 and ground-level ozone, which can exacerbate risks of premature death from cardiovascular disease, lung and kidney diseases.

NOx also matters in the energy transition. If you want to fit a combustion facility with CCS, it may be necessary to strip out the SOx then the NOx upstream of the amine unit, to avoid the formation of highly toxic nitrosamines (note here). High adiabatic flame temperatures of hydrogen will also form NOx. Meanwhile, using low-carbon ammonia as a fuel may release higher-than-normal NOx emissions as the NH3 molecule combusts (note here).

Selective catalytic reduction (SCR) has been used since the 1970s, using a metal oxide catalyst on a honeycomb ceramic or pleated metal sheet, to reduce NOx into harmless N2 and H2O. 4 NO + 4 NH3 + O2 ↔ 4 N2 + 6 H2O. The reaction uses ammonia or urea as a reducing agent.

History. The US already has about 1,000 SCR plants running, including at 650 CCGTs and 300 coal plants. We compiled data into the emissions of real world combustion facilities. Hence what are the costs?

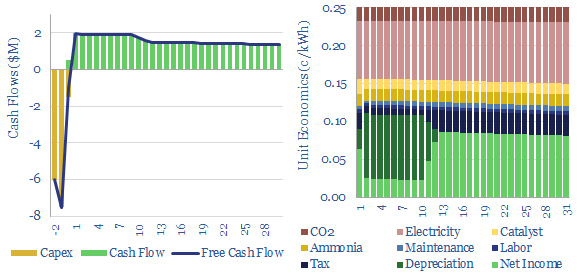

Our base case model captures Selective Catalytic Reduction costs at a combined cycle gas-fired power plant. Untreated emissions might be 50-75ppm, and a $50/kW SCR can reduce this to 2-5ppm. Our base case cost increment is 0.25 c/kWh for a 10% IRR. This equates to a NOX removal cost of $4,000/ton. The numbers also include a 1.3% energy penalty and a 0.005 kg/kWh uptick in CO2 intensity.

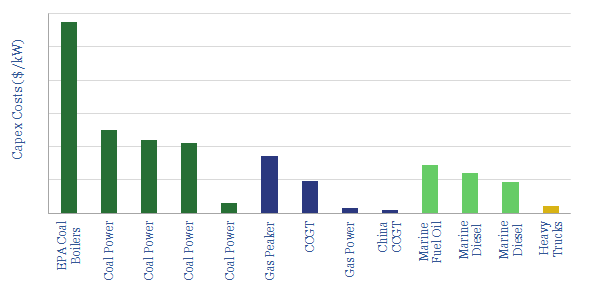

Variations of the model capture the costs of NOx removal at a coal-fired power plant (about 2x higher, at 0.5c/kWh) and at a marine diesel engine (0.7c/kWh). Although as is shown in the chart below, capex costs and ultimate costs are very sensitive to context, specifically, how much NOx is in the exhaust gas to begin with, and how much is removed.

Please download the data-file to stress tests Selective Catalytic Reduction costs for NOx removal, in c/kWh and $/ton of NOx. The model is configured so that you can flex the capex, opex, catalyst costs, NOx removal, maintenance, labor, CO2 prices, tax rates and capital costs (hurdle rate).