Cognex machine vision technology is used to ID products, inspect products, guide robotics and gauge sizes. This data-file reviews 20 case studies, with payback periods typically below 1-year. Increasing capabilities of AI are already extending use cases for these systems. We conclude this trend will continue, and also unlock more demand for industrial robots.

Cognex was founded in 1981, has 2,000 employees, is headquartered in Massachusetts, USA, listed on NASDAQ, with $4.7bn of market cap at the time of writing, having generated $915M of revenue in 2024 at a 12.5% operating margin.

The company develops machine vision solutions, which can be used in production lines and warehousing, to identify bar-code IDs, inspect products, guide robotics and gauge sizes.

The market for machine vision is around $8bn pa, Cognex estimates it has 15% share (its main rival is Japan’s Keyence), and aims to drive growth through this market, having grown revenues by 14% pa from 2011->2021.

Cognex estimates that 360M factory workers worldwide include 35M visual inspectors. Mega-trends that are driving machine vision sales are near-shoring, labor shortages due to demographics, and the ongoing need for quality/cost optimization.

Interesting questions to consider are whether the rise of AI will unlock more applications for machine vision, and in turn, unlock more opportunities for robotics.

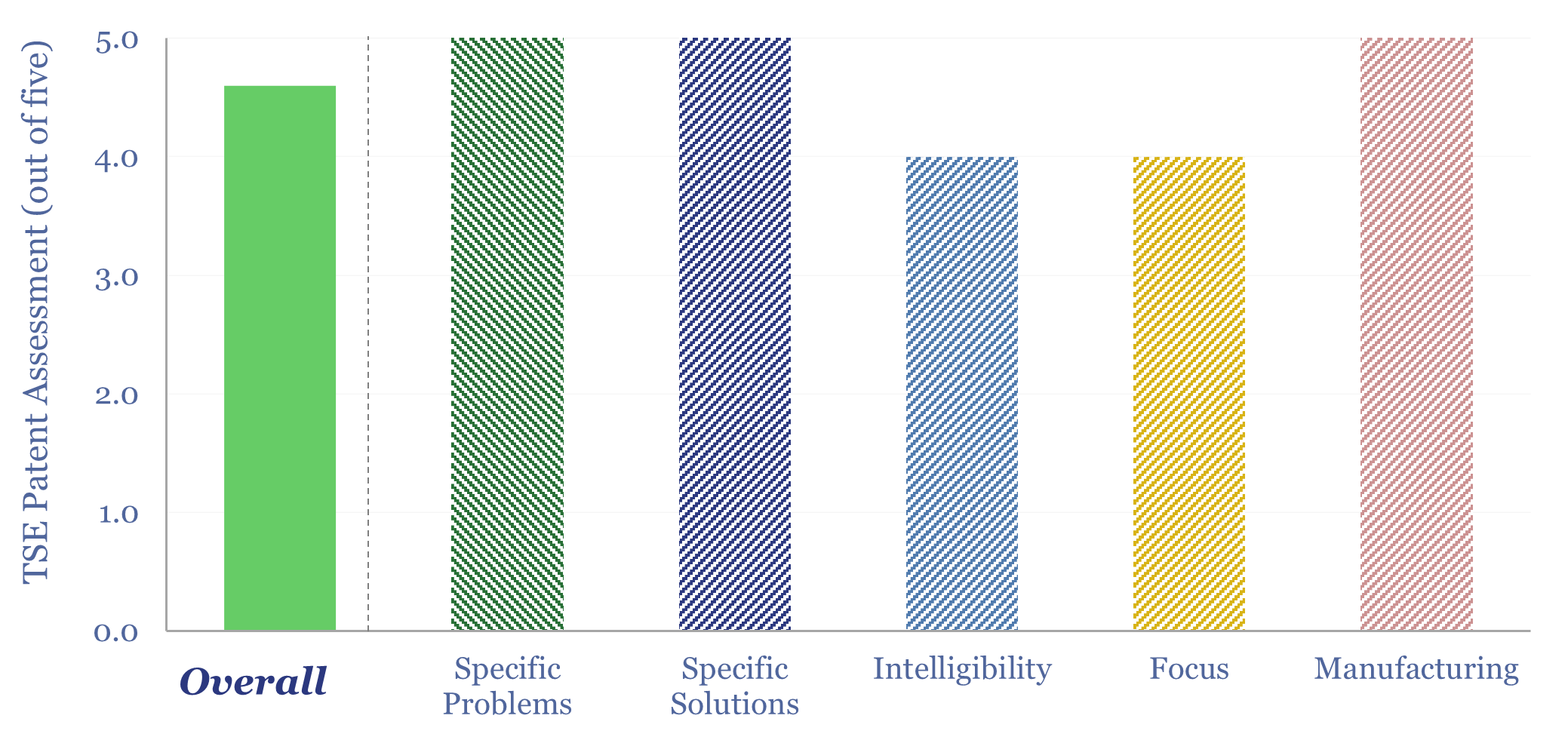

Cognex has 1,400 patents issued and pending, across 618 patent families in Espacenet. However, we found there were more helpful disclosures available from reviewing 20 Cognex case studies.

Across the case studies we reviewed, 90% lowered labor requirements, 80% reduced costs, 75% increased throughput, 70% improved quality, while the average payback time on the up-front investment was 9-months.

Specific systems cited in the case studies tended to increase error detection from 85-95% to 99-100%. Throughput rates for these inspection systems ran from 60-1,500 pieces per minute.

Many of the case studies highlighted that better vision is emerging, helped by AI, in applications that would previously have been “too complex to program”. Hence we do think AI will unlock more deployment.

A surprise from reviewing the case studies was how important lighting is to ensure good performance of machine vision systems. Many of the case studies agonized about adding LED lighting. Many of Cognex’s products have in-built LEDs.

Other surprises, conclusions into Cognex machine vision technology, and summaries of the case studies are available in the data-file. It is also interesting to review the reasons that machine vision systems were awarded to Cognex vs competitors.