Bioleaching uses bacteria to metabolize insoluble sulfides and iron complexes. It produces 20% of the world’s copper, and other metals; with 50% lower capex, at least 50% less CO2 and up to 80-90% recoveries; but it is currently limited to specific mineralogies. An exciting prospect for the 2020s is that new technologies may unlock more minerals for bio-leaching. This data-file is an overview of 20 bioleaching case studies.

Bioleaching produces 20% of the world’s copper, and is also used in other metals, as naturally occurring bacteria – such as Acidobacillus ferrooxidans/thiooxidans – metabolize iron, and oxidize insoluble sulfides, releasing valuable metal ions into solution. From here, they can be concentrated via solvent extraction and refined via electrowinning.

The advantages of bioleaching are low costs and low CO2, as per broader heap leaching operations. The entire process likely costs $4,000-5,000/ton, which is approximately half the level of integrated mining-smelting operation. Avoiding smelting also avoids around 2 tons/ton of CO2 emissions, which is also around a 50% reduction (model here).

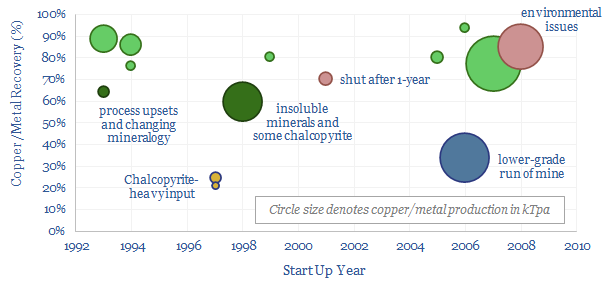

The technology is mature. This data-file tabulates over 20 examples. The first full-scale commercial success was 1982, with an acceleration in the 1990s. The median average size is small, at 20kTpa. But there are also world-scale operations using bio-leaching, such as BHP’s Escondida and Spence assets in Chile, both close to 200kTpa.

However mineralogy matters. Recovery rates average above c80%, when copper ores are chalcocites (Cu2S), covellites (CuS) and other easily leached minerals. Historically, these higher recovery rates have also been achieved on low-grade copper resources, averaging 0.5% copper, and sometimes as low as 0.3%.

Conversely, chalcopyrites (CuFeS2) make up over 70% of the world’s remaining copper resources and they cannot easily be leached, as a passivating layer forms at their surface. At best 20-25% recovery rates are reported when leaching chalcopyrite-heavy ores.

There is reason for excitement in the 2020s, as several companies are developing bio-leaching technologies that can recover copper from chalcopyrites. We have previously written about Jetti Resources. Rio Tinto has also developed a new process called Nuton. At best, CO2 may be 90% less than smelting.

20 bioleaching case studies are laid out in the data-file, as a useful overview, while we also see growing importance for metals and especially copper in our energy transition research.