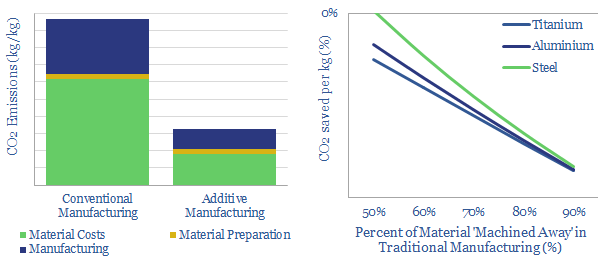

Manufacturing metal components can be extremely energy intensive, emitting 50-250kg of CO2 per kg of finished parts, as 60-95% of original materials are machined away in the manufacturing process.

This is where additive manufacturing is able to deliver c65% CO2 savings, per kg of materials, in our base case. The savings will be greater for more energy-intensive material inputs and when >80% of materials are machined away in the manufacturing process.

This data-file quantifies the CO2 savings of additively manufactured processes versus conventional manufacturing processes in kWh/kg and kgCO2e/kg. The calculations include material costs, preparation, machining and additive manufacturing itself. Our numbers are based on technical papers.