This data-file aims to give a helpful, basic overview of the world of compressors. The global market is c$40bn per year, growing at a 3% CAGR, which may accelerate in the energy transition. We outline how centrifugal, reciprocating and screw compressors differ, the energy requirements of compression, compressor costs and leading companies.

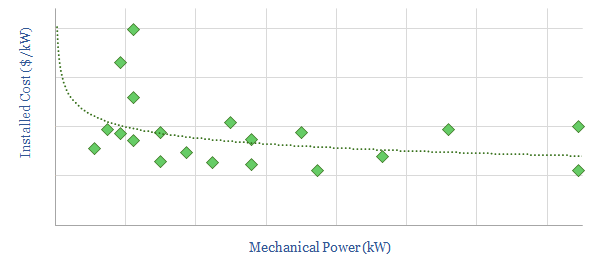

Next we tabulate costs. A typical industrial compressor might be around 50kW, enough to boost about 2m3 per second of air to the same pressure as a car tire (calculations are given). This might typically cost around $850/kW on an installed basis (data above).

In the energy industry, larger compressors can surpass 10MW-scale. Costs can vary by around 10x depending on the context. For example, we think that CO2 compressors will command a premium, maybe around $2,000/kW, due to higher-spec materials, the need to handle high pressures and densities, and other complexities of CO2 compression.

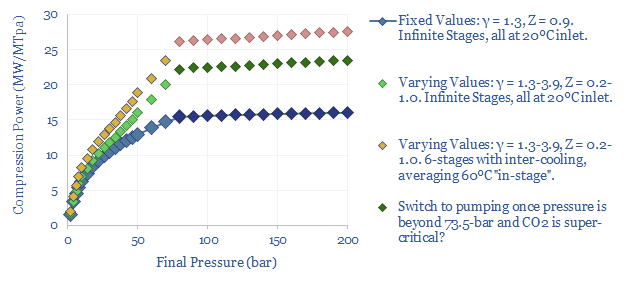

The data-file also includes a calculator breaking down the energy required for compression from first principles. As a good rule of thumb, compressing a gas stream to 80-200 bar (the kinds of pressures needed for CCS) might require 90-120kWh/ton of energy.

In power-sizing terms, we think it will require 6MW of compression power to reach 6-10 bar liquefaction pressures. And it might require 20-30MW of compression to reach 50-150 bar pressures for CCUS and CO2 disposal. The numbers are as complex as you want to make them, depending on how you reflect the weird thermodynamic properties of CO2 gas.

Some of the largest companies are also profiled, but the industry is led by Atlas Copco and Ingersoll Rand. Full details on compressor costs — capex in $/kW and energy usage in kWH/ton — are tabulated in the data-file.