DC-DC power converters are used to alter the voltage in DC circuits, such as in wind turbines, solar MPPT, batteries and digital/computing devices. This data-file is a breakdown of DC-DC power converters’ electrical efficiency, which will typically be around 95%. Losses are higher at low loads. We think there will be upside for increasingly high-quality and efficient power electronics as part of the energy transition.

What are DC-DC converters and why do they matter?

DC-DC converters are used to alter voltage and current in DC circuits. The global market is $15-20bn per year and growing at 12% per year. These devices are used seemingly everywhere as the world electrifies. From IT equipment and smartphones, to the MPPT in solar, to wind turbines, to charging and discharging batteries, such as in electric vehicles.

DC-DC converters invariably contain one or more MOSFETs, diodes, inductors and capacitors. Think about the MOSFET as a fast-acting switch, the inductor as resisting change in current (voltage fluctuates instead, as energy is stored in an expanding and collapsing magnetic field) and the capacitor as resisting change in voltage (current fluctuates instead, as energy is stored in an expanding and collapsing electric field).

In a buck converter, voltage is lowered. The MOSFET turns the entire circuit on and off. Power can only flow from the source to the load for a fraction of the time. But the inductor and capacitor keep the output voltage and current relatively stable. It follows that the delivered voltage will be some fraction of the input voltage, depending on the percent of time that the MOSFET is on (aka the duty cycle).

In a boost converter, voltage is raised. When the MOSFET switches on, it short-circuits the inductor. A spike of power flows into the inductor, creating an electromagnetic field. Then when the MOSFET turns off, this electro-magnetic field collapses, creating a sharp burst of higher voltage. Again the capacitor keeps the output current relatively stable.

What determines DC-DC power converters’ efficiency?

But what is the efficiency of a DC-DC converter? We think a good base case is around 95%, which is an optimized balance across a dozen different input variables. We think value will accrue to leading semiconductor and power-electronics companies, that can improve the efficiency of electrification technologies. Recent examples include Silicon Carbide (SiC) semiconductor, Zero-Voltage Switching.

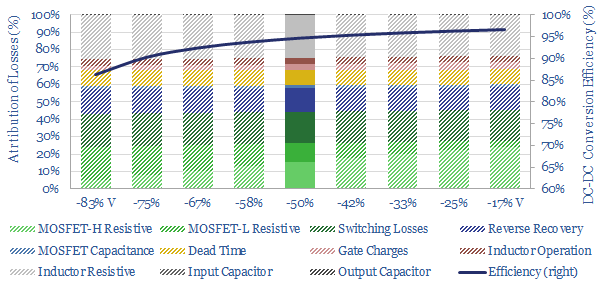

Step-up or step-down ratio. In our model, we have captured a buck converter, where in the base case, the voltage is being stepped down by 50%. This is what underpins our 95% efficiency calculation. However, the efficiency falls to only 90%, if we step-down by 75%, as effectively all of the losses rise proportionately.

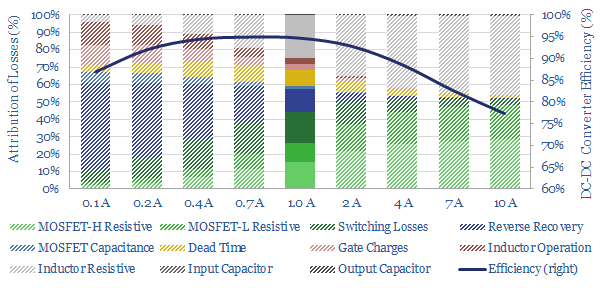

Power output. We also optimized our device for a nominal 1.0 Amps of current. At 10x lower current, efficiency falls to 87% as reverse recovery losses in the diode become disproportionately large. At 10x higher current, efficiency falls to 77% as inductor losses become disproportionately large.

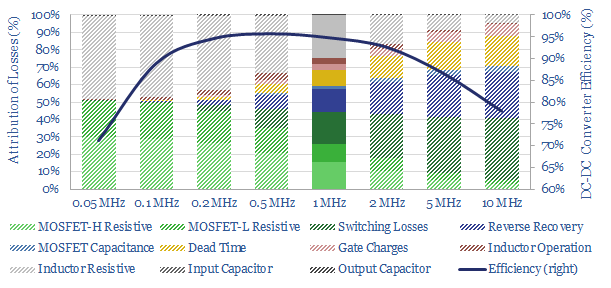

Switching frequency. We optimized our device for 1MHz switching frequency. At 0.1MHz, efficiency falls to 89% and the losses are dominated by resistance in the MOSFETs and inductors. At 10MHz, efficiency falls to 78% and is dominated by the switching loss and reverse recovery loss on the diode.