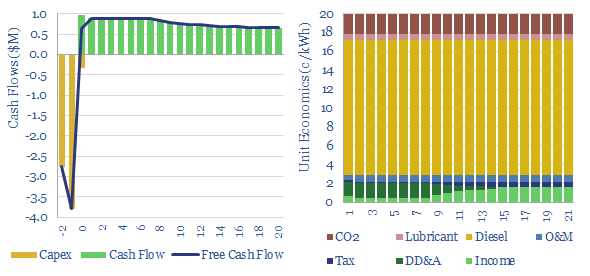

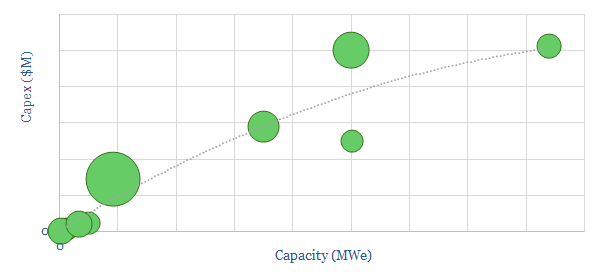

A multi-MW scale diesel generator requires an effective power price of 20c/kWh, in order to earn a 10% IRR, on c$700/kW capex, assuming $70 oil prices and c150km trucking of oil products to the facility. Levelized costs of diesel power generation can be stress-tested in this economic model.

A diesel genset includes an engine, power generator, switchgear, control systems, fuel supply systems, coolant and lubrication systems, a foundation, powerhouse civil works and wiring towards the connected load.

In the fuel cycle, air is drawn into the cylinder, compressed by 14-25x so its temperature reaches 700-900ºC, then a metered quantity of injected diesel spontaneously ignites, which provides the power to turn a rotating shaft, usually at 1,500-3,000 rpm (gas comparison here).

Total CO2 intensity is 0.6 kg/kWh for a diesel generator, at 40% average electrical efficiency, and including Scope 1, Scope 2 and Scope 3. This creates a rationale for expanding power grids and hybridizing diesel generation with solar and wind.

Some sensitivities are that each $10/bbl on the oil price translates into a 2c/kWh variation in power costs. For remote locations, each 100km of trucking distance adds another 0.2 c/kWh to the power price.

Capex costs can vary +/- 50%, especially depending on the emissions clean-up downstream of the generator (e.g., Diesel generators tend to be Tier 4, which emit 94% less NOx and 91% less particulate than Tier 2).

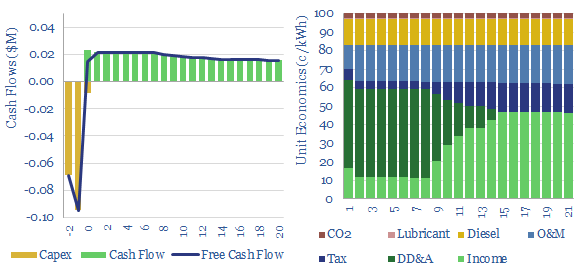

Another context where diesel generators are used is as a back-up power solution. Federal regulations require critical infrastructure, such as hospitals, care homes, airports, to have backup generators with 48-96 hours of fuel supplies. While facilities with risks of product spoilage might also have on-site generators to protect against grid failures, hence a typical super-market maintains a 250kW generator with 36 hours of fuel. When regulators talk of banning fossil fuels, it is not entirely clear what alternative is envisaged for these contexts.

The effective power price can be calculated for back-up generation systems, and might translate into around 100-200 c/kWh, depending on how frequently they are used. Although strictly, back-up generators exist to avoid much larger costs associated with power failures, rather than connoting a general willingness to pay 100-200c/kWh for electricity.

Companies with leading market share in diesel generators include Caterpillar, Generac, Cummins, Atlas Copco, AKSA, Aggreko.

Please download the economic model, to stress test the levelized costs of diesel power generation. The model allows for some easy flexing of power prices (c/kWh), capex costs ($/kW), oil prices ($/bbl), delivered diesel costs ($/gal), O&M costs ($/kW/yr) and CO2 prices ($/ton).