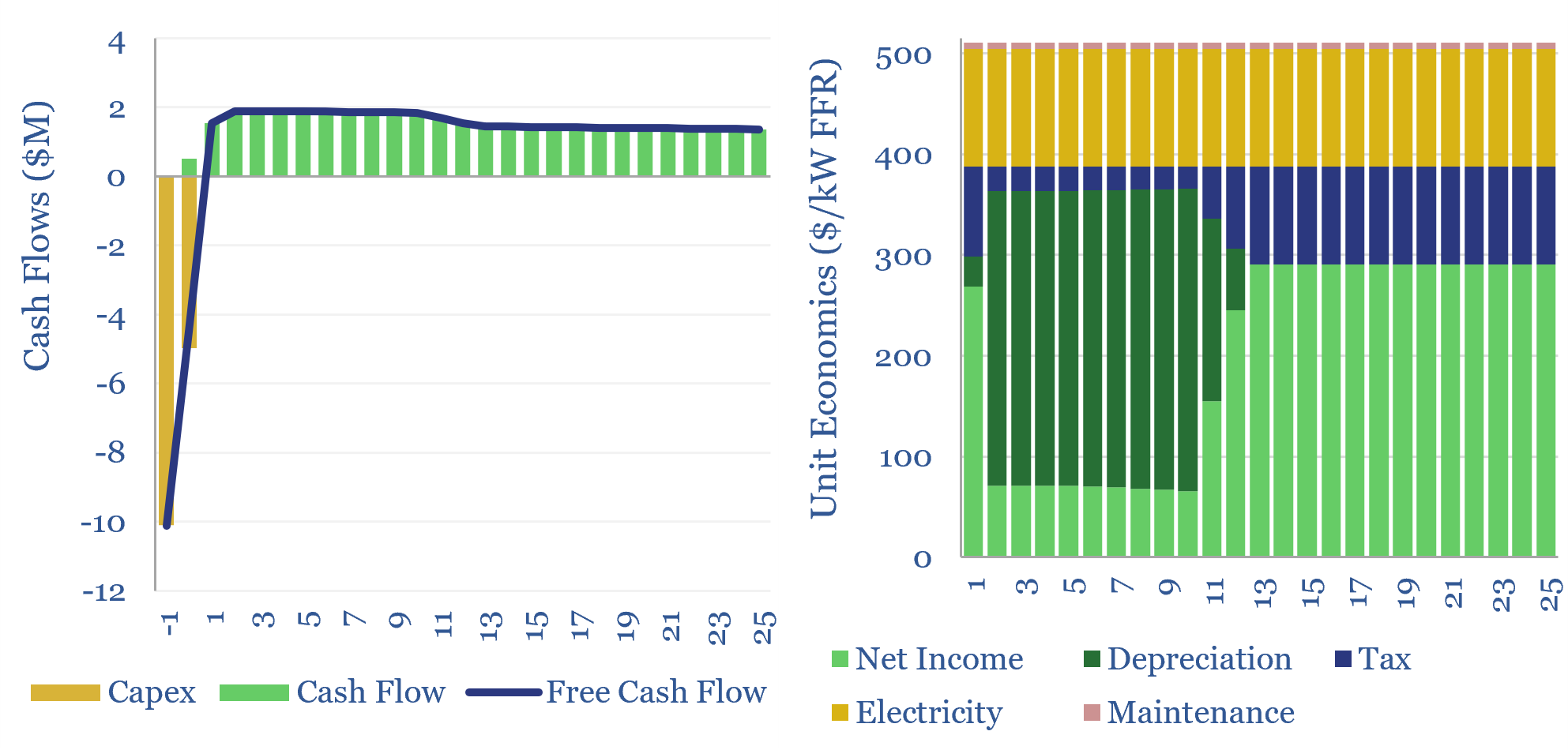

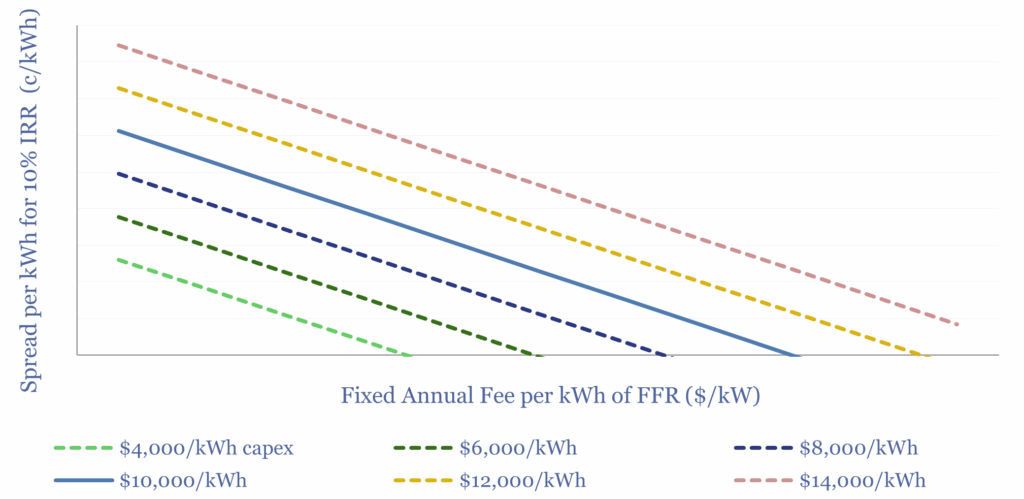

The economics of flywheels can be stress-tested in this data-file, requiring a $500/kW fee for fast-frequency response, to generate a 10% IRR on c$10,000/kWh of capex costs, on a typical flywheel plant with around 15-minutes of energy storage. The rise of renewables and AI increasingly requires adding inertia to power grids. Flywheels may be one solution.

A flywheel stores energy in the rotating mass of a large magnetically levitated disc, often made of carbon fiber, which can be accelerated up to 15,000 rpm by electric motors. Energy can later be released by using the inertia of the wheel to drive an AC generator.

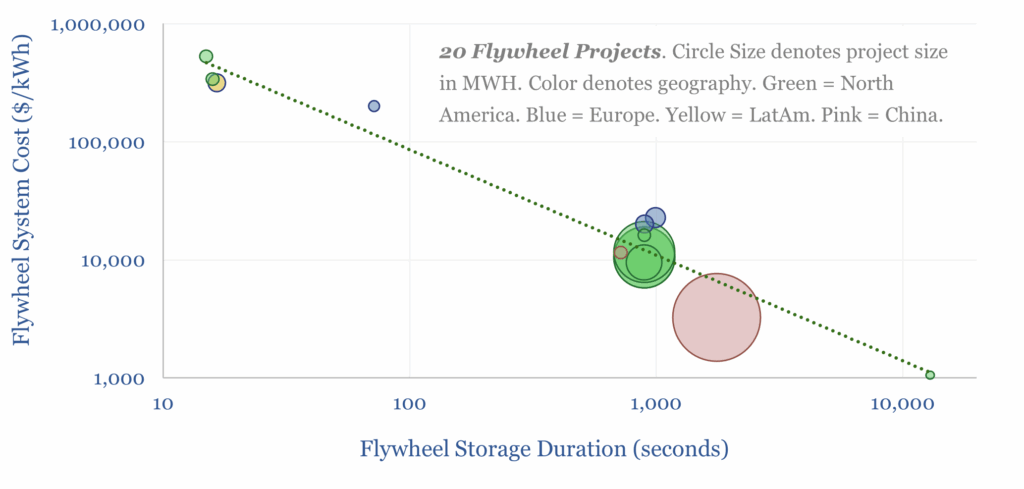

20 flywheel projects are tabulated in this data-file, ranging from 0.1-30MW of rated power and 0.01-15MWH of energy storage, at the project level. However, the projects are often modular, consisting of up to 200 individual flywheels.

Fast frequency response is supported by these flywheels, providing inertia to grids and AI data centers. One study cites a response time of 250ms. Another project cites a 4-second response time, which is “100x faster than traditional generation”. Although this is still slower than FACTS.

In another fascinating example, combining a flywheel with a coal plant was more gracefully able to smooth out the grid, while avoiding inefficient ramps at the coal plant, reducing fuel consumption by 1%.

As opposed to lithium ion batteries, which tend to have 3,000 – 10,000 cycle lives, due to battery degradation, flywheels in this data-file are expected to have 200,000 to 1M cycle lives, over around 20-years.

A typical flywheel stores about 15-minute of energy, for a capex cost of $3,000/kW and $10,000/kWh. Hence we can model the economics of flywheels for fast frequency response (synthetic inertia).

The economics of flywheels can be covered by a fixed fee (in $/kW terms) for providing fast frequency response to grids, or by a spread on energy that is stored and later re-released (in c/kWh terms), or by a combination of the two (chart below).

For renewables, one could argue that each MW of installed capacity requires 0.1-0.2MW of flywheels to match the inertia of large rotating generators, which inflates true levelized costs of wind/solar by $50-100kW? (And this kind of fast response goes beyond the role of lithium ion batteries for when the wind is not blowing and/or the sun is not shining, as covered here).

The economics of flywheels are covered in this data-file, across capex costs, opex costs, input energy, round-trip efficiency, availability, charge-discharge cycles per year, and the capital costs needed for a 10% IRR.