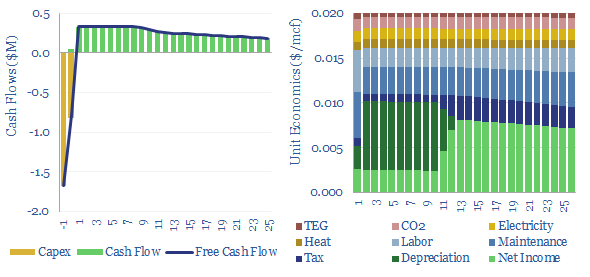

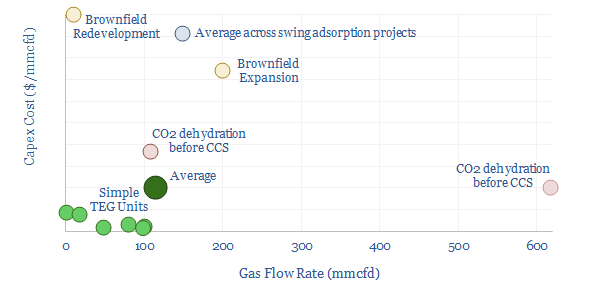

Gas dehydration costs might run to $0.02/mcf, with an energy penalty of 0.03%, to remove around 90% of the water from a wellhead gas stream using a TEG absorption unit, and satisfy downstream requirements for 4-7lb/mmcf maximum water content. This data-file captures the economics of gas dehydration, to earn a 10% IRR off $25,000/mmcfd capex.

Wellhead gas might have up to 0.2% water entrained within it (100lb/mmcf). This should ideally be reduced by 90-95%, to below 7 lb/mmcf, sometimes below 4lb/mmcf.

The main reasons for reducing the water content of natural gas are to avoid issues in downstream equipment and pipelines, such as plugging or hydrate formation. For example, as an LNG plant cools the gas stream to -160C, any water is clearly going to freeze out.

Dehydration is also necessary for other gas streams. For example, some of the recent projects that have crossed our desk are aimed at dehydrating CO2 in CCS projects, so that it does not form carbonic acid and dissolve disposal pipelines. Hydrogen may also require dehydration, downstream of a reforming unit or some electrolysis plants.

Gas dehydration most commonly takes place by absorbing the water in tri-ethylene glycol (TEG). TEG acts as a solvent for water at ambient temperatures in an absorber unit. Then the water can be stripped from the TEG solution by heating to 200ºC in a reboiler unit. Many readers will note this is effectively the same plant configuration as for post-combustion CCS using amines.

The global TEG market is worth around $800M per year, implying c500kTpa of production at $1.5-2.0/kg. TEG is made via the step-wise oligomerization of ethylene oxide.

In our base case model, gas dehydration costs $0.02/mcf to earn a c10% IRR while covering the capex of the TEG unit, using up 0.03% of the energy in the gas itself (i.e., a 0.03% energy penalty) and adding 0.03 kg/mcf to the CO2 intensity of gas.

This data-file allows for stress-testing of TEG unit capex (chart below), maintenance, electricity use, heat consumption, CO2 prices, TEG make-up costs and other opex costs.

TEG dehydration units are under increasing scrutiny due to methane emissions, including from pneumatically powered components.

Alternatives to TEG dehydration units include solid sorbents and molecular sieves. For an overview, see our note into swing adsorption.

But we think the most interesting read across from our gas dehydration model is for CCS/DAC. Using this fully mature technology, for which over 200,000 units have been installed to-date, we think the costs “per ton of water removal” still equate to $450/ton and the capex costs equate to around $5,000/Tpa. Details in the data-file.