Hillcrest Energy Technologies is developing an ultra-efficient inverter, which has 30-70% lower switching losses, up to 15% lower system cost, weight, size; low thermal management needs, high reliability, and confers up to 13% higher range than today’s inverters, especially for use in EV powertrains; but also in wind, solar, batteries and fast-chargers. It is based on SiC semiconductors. This Hillcrest technology review presents our conclusions from patents and technical papers.

Hillcrest was founded in 2006, is based in Vancouver, Canada with c15-20 employees. It is publicly listed, with market cap of $25M (Feb-23) and shares traded on the OTCQB Venture Market and Frankfurt Stock Exchange.

It is developing a Zero Voltage Switching (ZVS) inverter. What does this mean, and why does it matter?

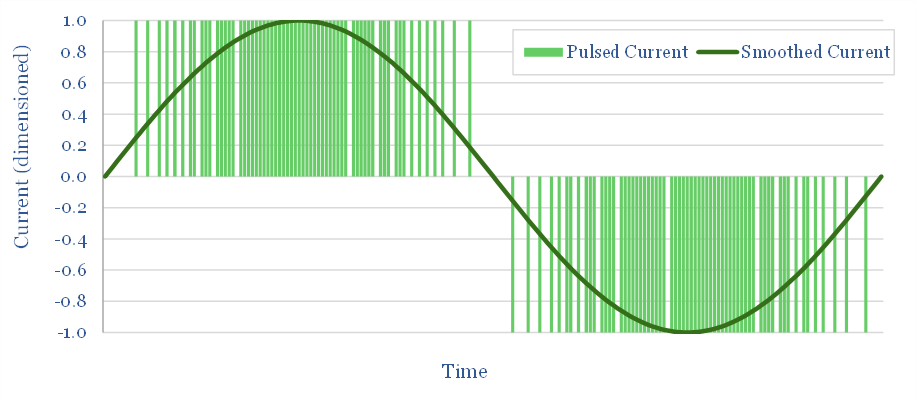

Inverters convert DC power to AC power via pulse width modulation, which is covered in our primer into electricity. Specifically, electrical switches create bursts of current, of increasing frequency, then decreasing frequency, then increasing frequency, then decreasing frequency. When these power bursts are averaged out, they resemble an AC sine wave (chart below). This AC power signal can be used to feed power into the grid, or to drive the electric motors in an electric vehicle. The switches are MOSFETs or IGBTs.

The quality of the AC power signal depends on the switching frequency. Fewer pulses (each with longer length and longer gaps) creates a jagged AC sine wave. Whereas more pulses (with shorter length and shorter gaps) produces a smoother sine wave. A nice analogy is thinking about how video quality increases with a higher frame rate. So why don’t inverters dial up the switching frequency to the max?

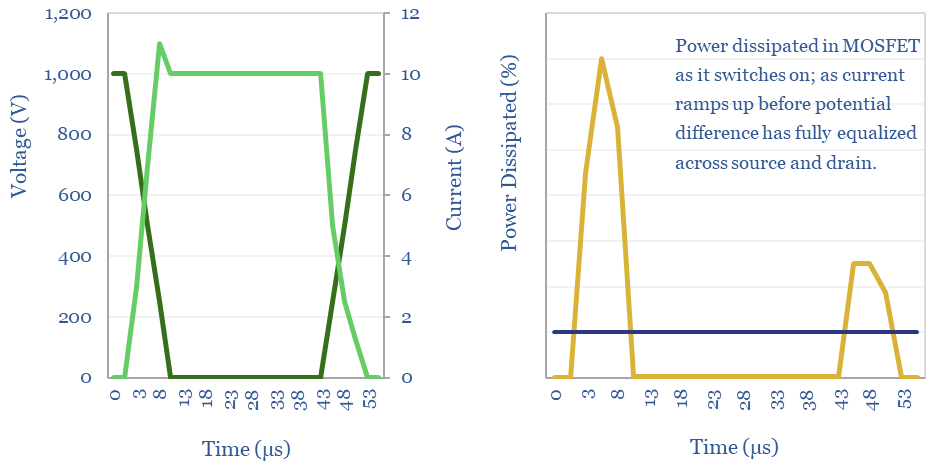

Switches incur a small power loss every time they switch on and switch off. The reason is that when the switch is off, there is a potential difference (aka a voltage) across the junction (dark green, chart below). When the switch starts to turn on, current starts to flow from source to drain (light green, chart below). The current ramps up as the voltage ramps down. And thus, in the middle, power is dissipated, as power = voltage x current (yellow line, chart below). And so usually, the higher the switching frequency, the higher the switching losses.

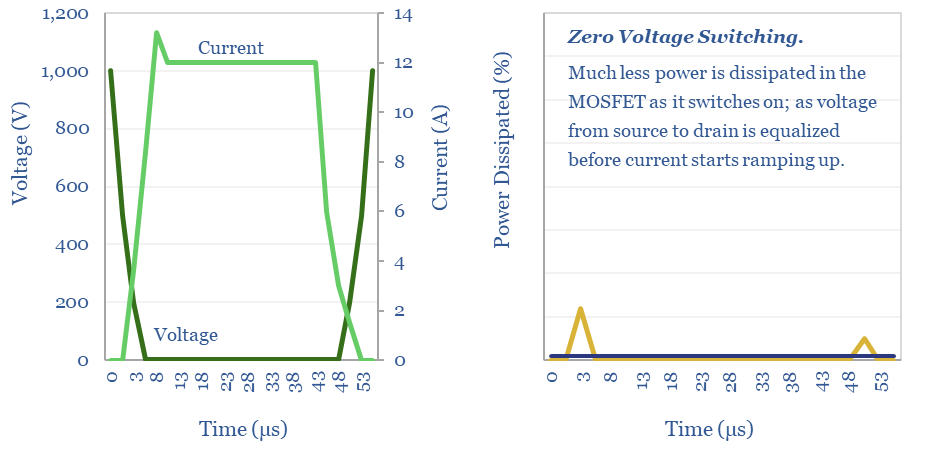

Zero Voltage Switching, as the name implies, cuts the voltage from source->drain towards zero BEFORE the current from source->drain ramps up. Thus the power dissipated per switching event (VxI) is very close to zero (chart below). This is conventionally done using active snubber circuits or software on micro-controllers. In principle, ZVS enables faster switching frequencies without astronomical switching losses.

Hillcrest’s technology includes Zero Voltage Switching algorithms, which can be implemented in a micro-controller, and coupled with next-generation SiC semiconductor, which are creating an exciting jolt forwards in the power electronics behind practically all of the core areas of the energy transition (TSE research note here).

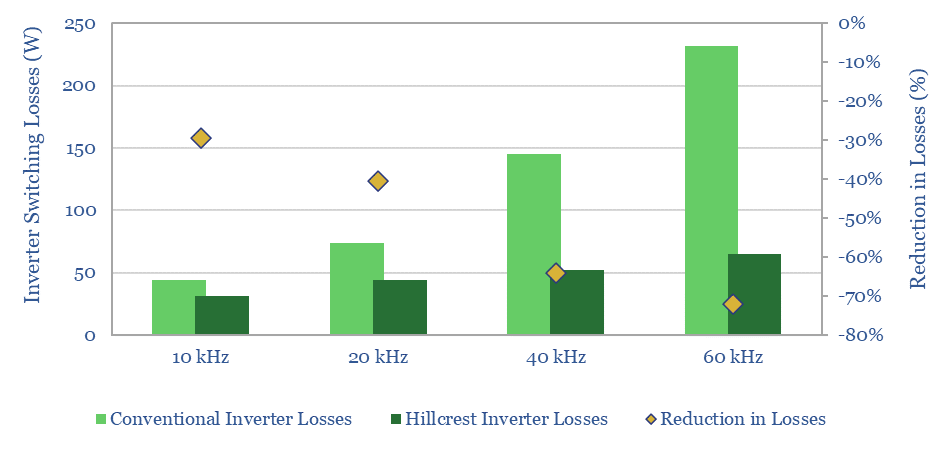

Hillcrest’s white papers show that its algorithms achieve 30-70% lower switching losses than others using similar semiconductor, especially at higher switching frequencies (chart below). They are also shown to operate over a wider operating range than existing solutions, and produce a particularly high quality output (low ripple, low harmonics, low EMI) .

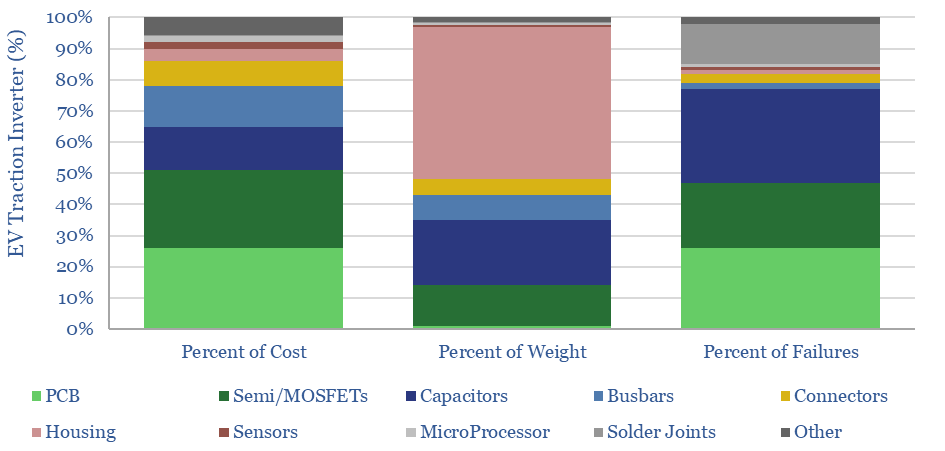

Another benefit highlighted is that higher quality power signals should allow for downsizing of other components in the traction inverter; especially the DC link capacitor, which typically comprise 21% of the weight of the inverter, 14% of its cost, and 30% of the failures (chart below). This should be interesting for manufacturers of electric vehicles, and others in wind, solar, batteries, fast-charging, power grids.

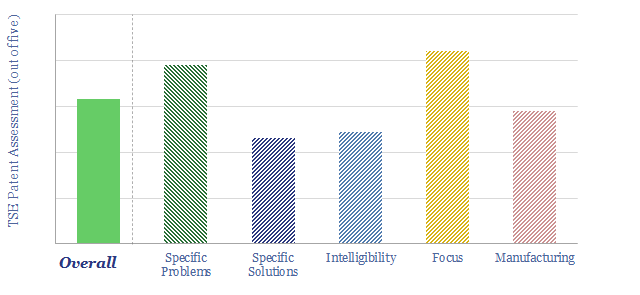

The data-file linked below is our Hillcrest technology review. As usual, our goal is to review the company’s patents, and its White Papers, to assess (a) can we understand precisely how the company is achieving a technical breakthrough? (b) can we de-risk that breakthrough and (c) can we find a clear moat around the technology, conferring an edge for the company.