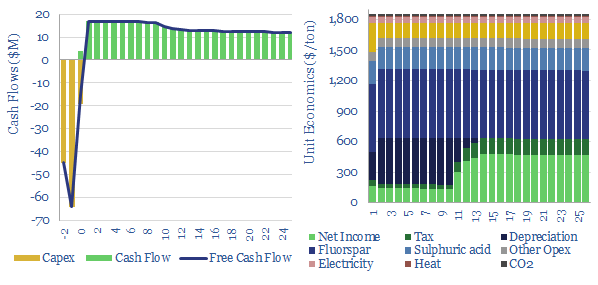

This economic model captures the costs of hydrofluoric acid production from acid-grade fluorspar and sulfuric acid. We think marginal costs are most likely around $1,850/ton, in order to earn a 10% IRR on a production facility costing $4,000/Tpa, while the fully loaded CO2 intensity is around 0.75 tons/ton.

Hydrofluoric acid is a crucial commodity chemical. It is used to make fluorinated polymers, as feature in solar, batteries, wind and power cables.

It is used to make cryolite, for aluminium refining, as is necessary for long-distance power transmission lines.

It is used to make refrigerants, as used in fridges, AC and heat pumps.

UF6 is used in upgrading uranium for nuclear fuel.

And HF is used in its own right, to etch silicon chips, metals and blow insulation foams.

This economic model captures the production of hydrogen fluoride from acid-grade fluorspar and sulfuric acid.

We think marginal costs are most likely around $1,850/ton, in order to earn a 10% IRR on a production facility costing $4,000/Tpa, while the fully loaded CO2 intensity is around 0.75 tons/ton. These numbers can be stress-tested in the data-file.

This data-file captures the costs of hydrofluoric acid production, including pricing, input costs, energy costs, labor rates, tax rates, and CO2 taxes.

Back-up tabs aggregate a build up into fluorinated polymer value chain (based on PTFE), fluorspar mining data by country from USGS and our notes from technical papers.