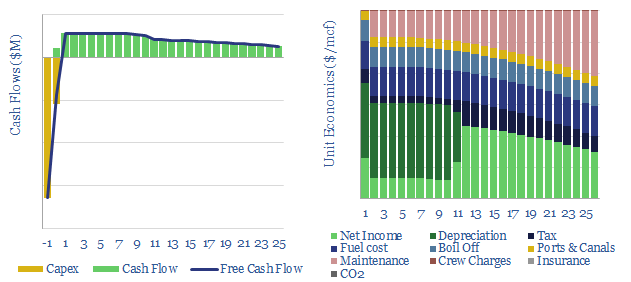

The purpose of this data-file is to model the economics of shipping large cryogenic cargoes, such as LNG carriers or even dual-purpose vessels that can carry both LNG and CO2. We break down LNG shipping costs, and day-rates needed to earn 10% IRRs, including capex, opex, fuel, maintenance and port fees.

Shipping an LNG cargo costs $1-3/mcf, while the most important input variable is the distance from source to destination. In our base case, we assume a distance of 5,750-miles, from the US to Europe, which yields a total transport cost of $130k/day or $1/mcf of delivered LNG.

Transportation distance is the most important cost driver for large-scale shipping. An LNG tanker pays a fixed ‘day rate’, it might cover 400 miles in a day, while its cargo also boils off at around 0.1% boil off rate per day. Hence the longer the journey, the higher the cost per cargo.

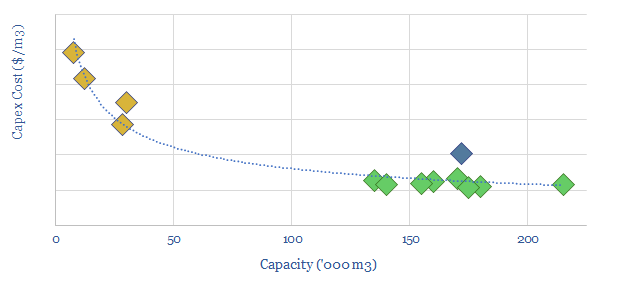

Vessel size is another cost driver, with economies of scale for larger and larger carriers. Capex cost data per vessel is shown below. A good base case is that a large new LNG carrier, with 170,000 m3 capacity will cost around $200M to construct.

Further details can be found in our broader LNG research and broader CCS research. The economics for shipping LNG in this model can also be compared with the economics of shipping CO2.

The purpose of this data-file is to help decision-makers quickly model the economic costs of LNG shipping, and other cryogenic cargo shipping. What day-rate is needed for a 10% IRR? What is the resultant effective shipping cost in $/mcf or $/ton? And how can these numbers be disaggregated between different input variables? Please download the data-file to stress test these inputs.