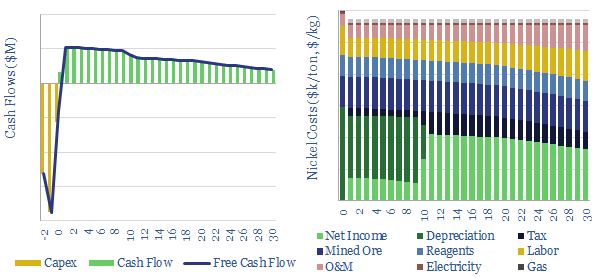

This model captures the economics of producing battery-grade nickel (e.g., Class I, nickel sulphate) at a metallurgical processing facility.

Marginal cost is likely around $11,500/ton in order to generate a 10% IRR, in a process emitting 14 tons of CO2 per ton of product.

However, economics can range from $10,000-20,000 tons and CO2 intensity can be as high as 40-80 tons per ton, using alternative processing pathways.

Costs are disaggregated to flex the impacts of nickel prices, cobalt co-revenues, materials costs, ore costs, labor costs, energy costs, CO2 costs, capex, opex, tax and other.

Back-up data are derived from company disclosures and technical papers, which are also summarized in the back-up tabs behind the main model.

Further research. Our latest commentary on the economics of producing battery-grade nickel is linked here. The screen on leading nickel producers is linked here. For an overview on global nickel supply and demand see our article here.