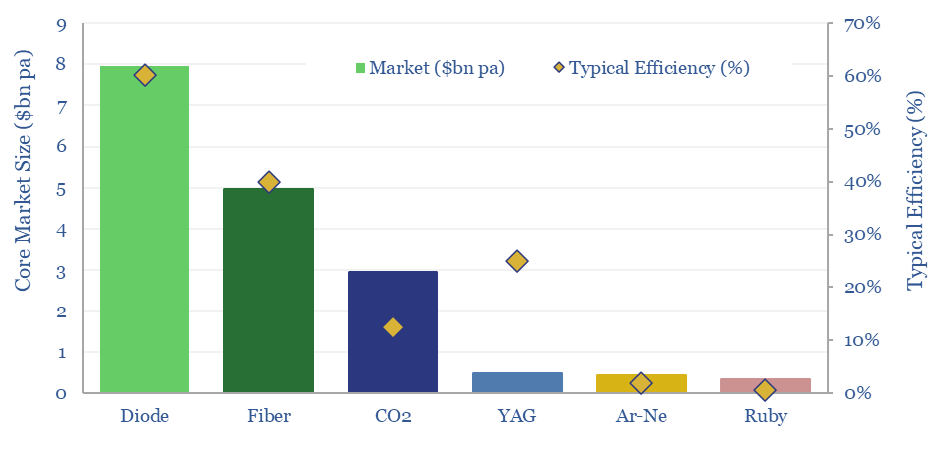

The global laser market is worth $20bn pa, of which half comprises diode lasers (mainly used for fiber-optic communications) and around 30% is fiber lasers (mainly used for cutting, welding and heat-treating materials). These two laser types dominate because of their high, 30-80% efficiencies. This data-file is a brief overview of lasers.

Ruby lasers were the first laser systems to be demonstrated, going back to Theodore Maiman at Hughes Lab in 1960. Ruby material is irradiated by a short pulse of light from a xenon-filled flashtube, forming a laser system with 3 energy levels. Cr3+ electrons are promoted to E3, which is unstable, falling quickly back to E2, which is meta-stable. Stimulated emission occurs for the energy jump from E2 to E1 at 694.3 nm wavelength.

Other laser types that followed included Ar-Ne, YAG (using yttrium aluminium oxide garnet, doped with neodymium Nd3+) and CO2 (actually an outlier in that this is a molecular laser, whose meta-stable state comes from vibration patterns of the CO2 molecule).

Diode lasers now make up around half of today’s market, however, as they are 30-80% efficient, easy to manufacture and can be integrated with other semiconductors. They are “Fabry-Perot resonators”, comprising PIN junctions (similar to the PN junctions in LEDs and other semiconductors), bounded by a fully reflective mirror on one side and a partially reflective mirror on the other side. Electrons are injected into the N-semiconductor and holes are injected into the P-semiconductor. The intrinsic semiconductor between them minorly delays the recombination so that stimulated emission can occur, and also acts as a channel through which the laser light can oscillate, between the two reflective mirrors, whose interval distance must be a precise multiple of the laser light half-wavelength. Laser pulses are emitted from the non-reflective mirror side, and focused via a lens. Limits of diode lasers are that these devices tend not to exceed 1kW, they need a heat sink due to heat generation, and their collimation is not perfect.

Fiber lasers make up around 30% of today’s laser market, but are somewhat confusingly named. The laser pulses for fiber optic cables tend to come from diode lasers (see previous paragraph). Whereas fiber lasers use an optical fiber as their gain medium, usually by doping the fiber with a Rare Earth element (e.g., erbium, ytterbium, neodymium, dysprosium, praseodymium, thulium, holmium), then applying a fully reflecting Bragg grating to one side and a partially reflective Bragg grating to the other side. The active gain regions can meters-kilometers long, to support 1-15kW typical continuous power outputs (and over 30kW in Yb-doped lasers). Efficiency is 30-50%. Fiber lasers comprise over half of the industrial laser market, of which the largest category, at 40% is for cutting metals. In recent years, China has been driving deflation through fiber lasers costs.

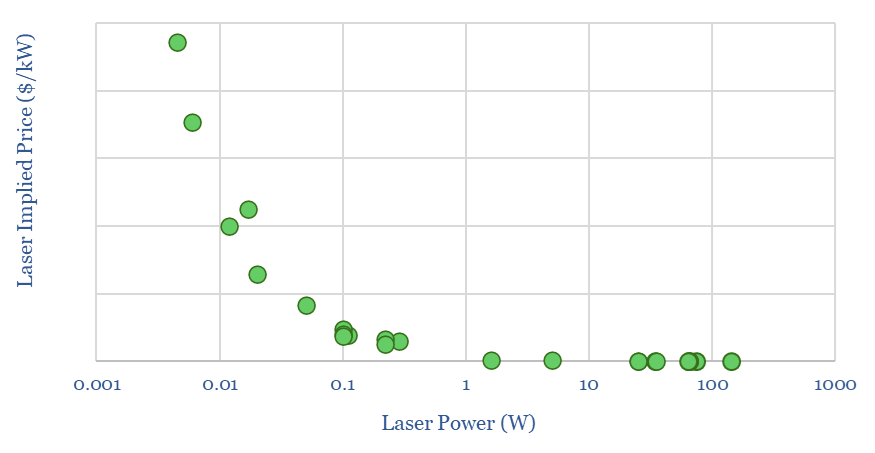

Laser costs are also tabulated in the data-file, particularly for diode lasers (chart below), which in turn feeds into our estimates for the costs of fiber optic cables.