Rare Earth recycling may recover Rare Earths at 50% lower costs and with over 90% less energy and CO2 than primary production, as long as the recycling process is simple, and only requires a small quantity of readily available commodity chemicals. This is exemplified by patents from REEcycle, which can recover over 90% of the Rare Earths in scrap magnets with over 99% purity.

REEcycle’s origins go back to scientific research at the University of Houston in 2012, culimating in a demonstration plant with the ability to recover 15 out of 17 Rare Earth Elements from electronic waste.

REEcycle currently plans to purchase scrap rare earth magnets and recover the materials for use in new magnets. The magnets will mainly come from end-of-life wind turbines, EVs, electric bikes and e-waste.

This matters as our recent research sees Rare Earths as a key enabler of AI, prone to supply disruptions in critical Rare Earth applications, and relatively long lead-times, high costs and high uncertainties on new Rare Earth projects.

REEcycle’s website alludes to a proprietary solvent that can recover 99.8% of Rare Earths from the magnets found in electronic waste, using a low-temperature procfess, which disposes of other waste materials (iron, boron) in concentrations compliant with municipal waste standards.

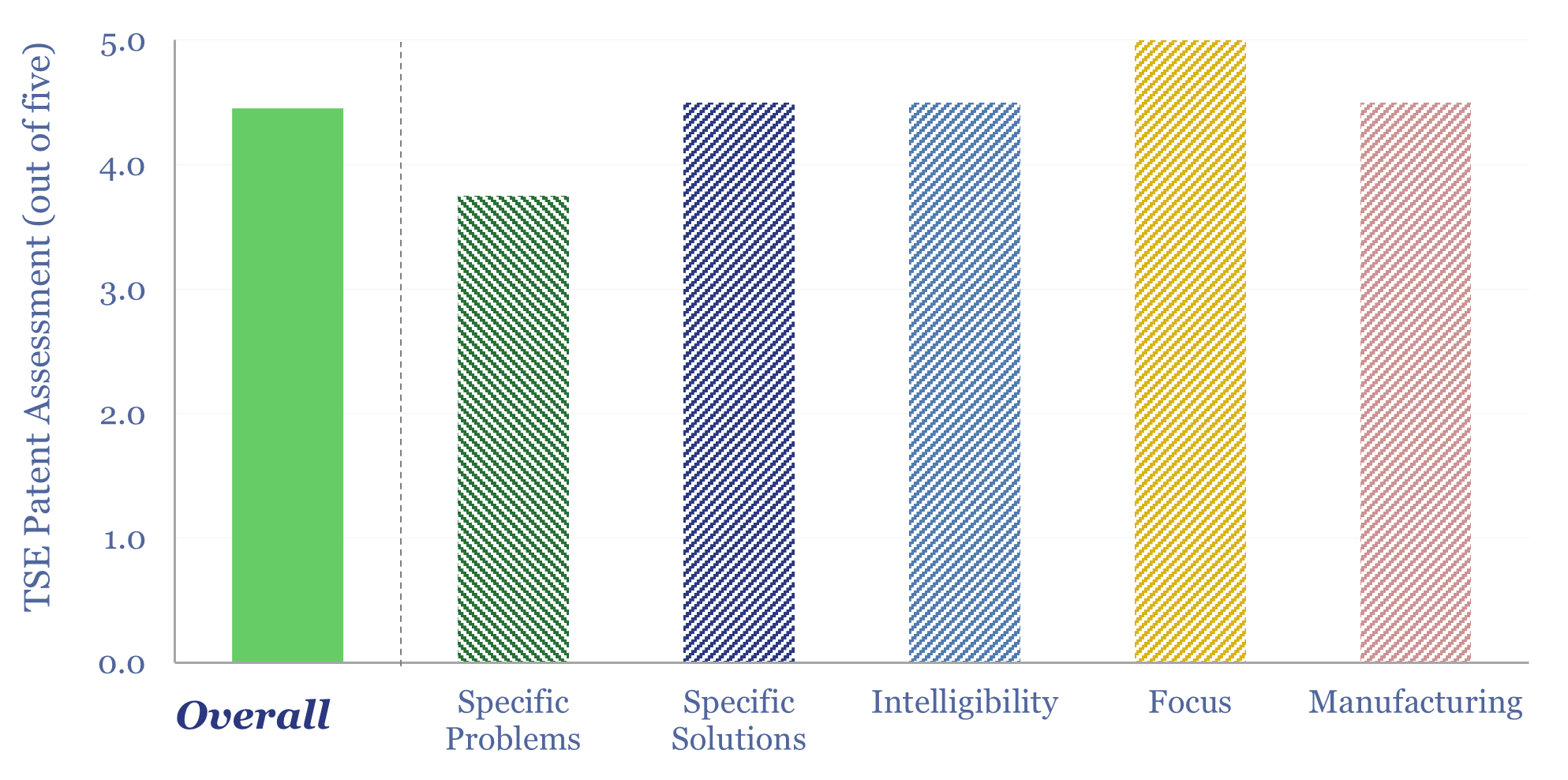

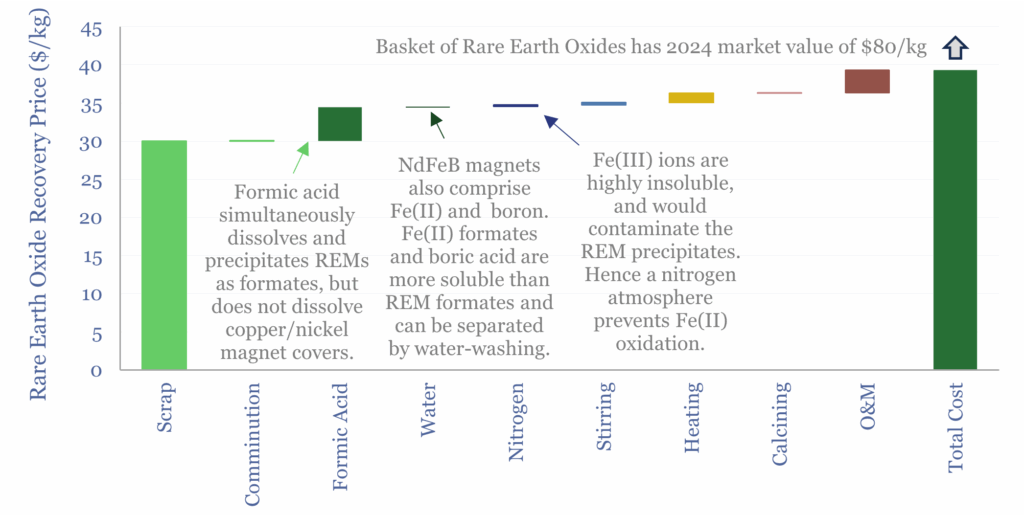

Our patent review allowed us to guess at how REEcycle’s technology works, the specific solvents, other chemicals use, energy use, and process costs (chart below). Details are in this data-file.

Overall, this makes us think that Rare Earth recycling has high potential as a future supply source in the developed world, at c50% lower costs and c90% lower energy intensity than primary production of Rare Earths. This is similar to other recycling value chains.