The costs of sugar production are estimated at $260/ton for a 10% IRR at a world-scale sugar refinery, in a major sugar-producing region. Higher returns are achievable at recent world sugar prices, and by valorizing waste streams such as molasses for ethanol and bagasse for cogenerated electricity.

Sugar is the crucial feedstock for one-third of the world’s 28bn gallons pa of bioethanol, or around 0.6Mbpd of biofuels; and as a sweetener across the world’s food system, with Western adults typically consuming 60-80 grams of added sugar per day. This data-file captures the costs of sugar production.

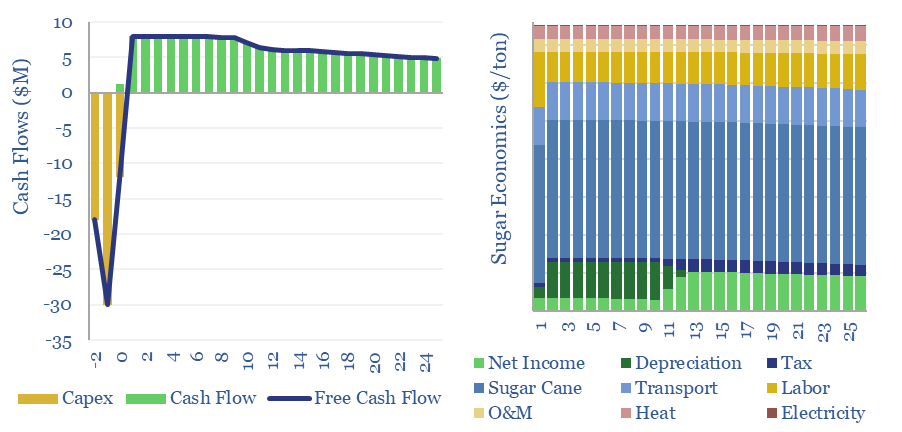

A sugar price of $260/ton is needed for a 10% IRR, on a MTpa-scale sugar refinery, while global sugar prices recently ranged from $400-750/ton, enough to unlock 30-60% IRRs at these facilities.

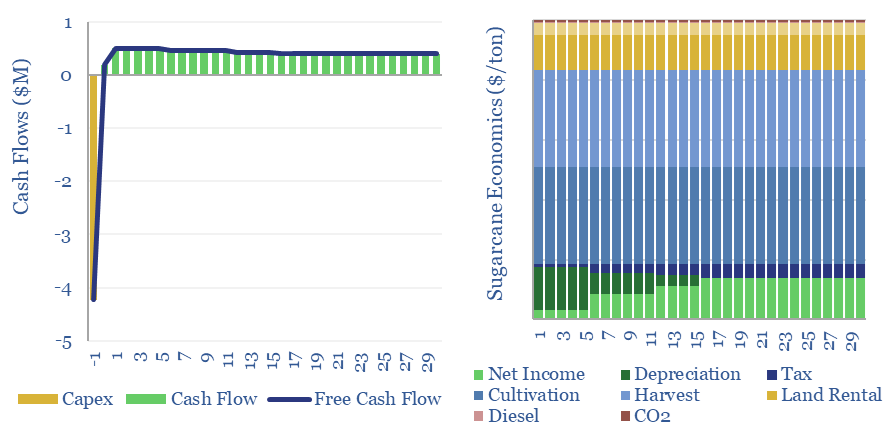

50% of the cost of sugar comes from sugarcane, as a feedstock, which is also built up from first principles in this data-file, averaging $25/ton in our base case. Prior to harvest, sugarcane typically comprises c55% moisture, 12% sugar, 20% fiber and 12% trash (which may be burned off or cut off and left in the field).

Costs of sugarcane are also sensitive to yields, which is a key reason that Brazil leads the world in biofuels production. Yields can average 110 wet tons per hectare, although also tend to vary year-by-year.

Sugar itself only comprises c60% of the revenues of a typical sugar refinery, with the remainder coming from non-edible molasses (useful as an input to ethanol production), bagasse (as a fuel) and cogenerated electricity. The prices of these components can also sway the economics of sugar refining.

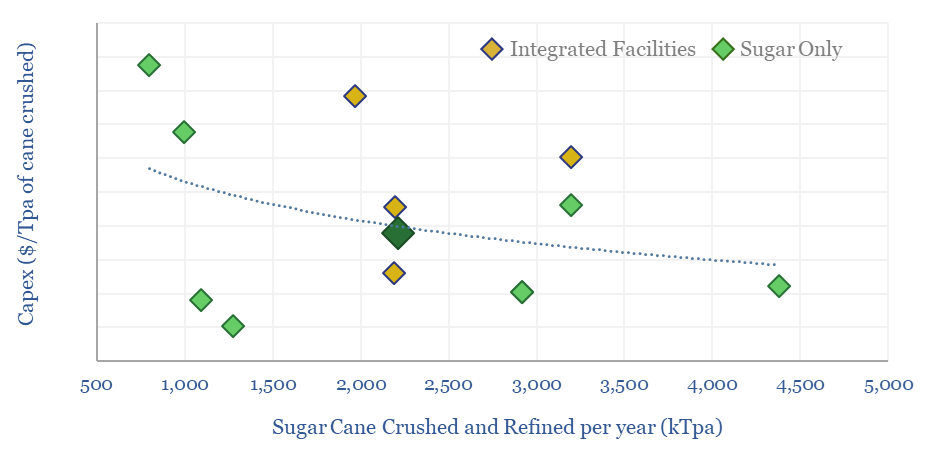

Capex costs and opex costs are built up in the data-file, using data from past projects and technical papers. Capex costs of sugar production plants can vary widely, depending on the country, and the specific details of what is actually built.

This data-file captures the costs of sugar production, energy use, CO2 intensity of sugar, plus a breakdown of capex and opex. It is an important input for stress-testing the costs of ethanol from sugar.