Tigercat is a private company, founded in 1992, headquartered in Ontario, Canada, with c2,000 employees. The company produces specialized machinery for forestry, logging, materials processing and off-road equipment. Our Tigercat patent review has found a moat around reliable, easy-to-maintain, mobile and efficient forestry equipment.

In the modern forestry industry, we think a crew of 1 x feller buncher, 1 x skidder and 1 x loader can harvest 250 tons of timber per day, with a fuel economy of 1.2 gals/ton of wood. This kind of productivity is up at least 150x from pre-industrial forestry.

We wonder whether there is increasing opportunity for companies in the forestry supply chains, as themes such as sustainable timber (e.g., cross-laminated timber), sustainable forestry, reforestation, sustainable packaging and biochar gain traction in the energy transition.

A key challenge for the industry is that off road machines are subject to higher stress levels, and forestry machines are subject to even higher stress levels. Key components subject to very severe operating loads are axles, wheel spindles, drivetrain components and pump drive gearboxes.

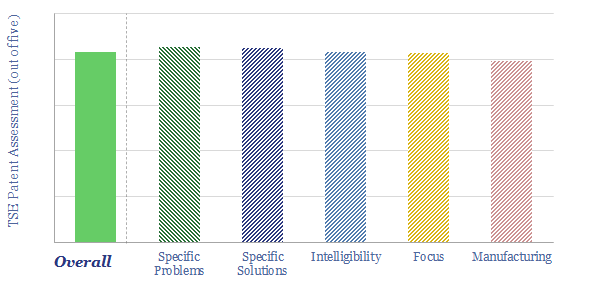

Overall, our Tigercat patent review finds an array of specific, intelligible and focused patents, improving the reliability, maintainability, mobility and fuel economy of forestry equipment.

This is especially applicable for harvesting equipment, such as feller-bunchers, mulching equipment, and novel areas that may matter in the energy transition such as site preparation, re-planting and biochar production. These are all focus areas in the patents.

We have profiled the CO2 credentials of different wood uses as part of our ongoing forestry research.