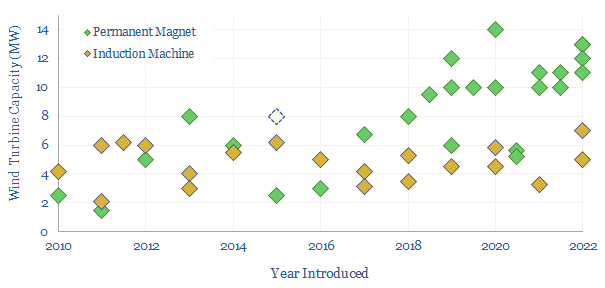

Wind turbine generators can use doubly fed induction generators (DFIGs) or permanent magnet synchronous generators (PMSGs) based around Rare Earth metals. This data-file captures the trends in DFIGs vs PMSGs over time by tabulating 40 examples, as turbines have grown larger, and different wind turbine manufacturers have adopted different strategies.

How do wind turbines generate electricity? Both doubly fed induction generators (DFIGs) and permanent magnet synchronous generators (PMSGs) retain a balanced market share in modern wind turbines, converting rotational energy into electrical energy.

For an overview of the different designs, please see our overview of magnets, overview of electricity and overview of wind power-electronics.

This data-file tabulates data into forty recent wind turbine designs, sampling across all of the leading wind turbine manufacturers. We have tabulated the model, manufacturer, country, capacity (MW), year introduced (YYYY), rpm, gear system, typical voltages (kV, where available), generator system and other power electronic details.

Capacity trends. The maximum power capacity for DFIG turbines has been hovering around the 6-8MW mark for the past decade, while the trend towards larger 10-15MW turbines, especially offshore, is almost always associated with PMSG turbines.

Why do wind turbines use Rare Earth magnets? The short answer is that Rare Earth magnets have greater magnetic field strengths (flux densities), which opens up direct drive generator configurations with much lower gearing, and without requiring their own input power supply like the electromagnets in DFIGs do.

Advantages of PMSGs are cited by different operators, including higher >96% efficiency, fault ride-through, lower maintenance, more compact nacelles, easier installation.

Elimination of gears is an advantage for PMSGs as it can help to avoid maintenance issues, which typically costs $40/kW of capacity and 1-2c/kWh on levelized cost. For geared turbines, the gearbox is by far the largest source of maintenance issues (data here).

About two-thirds of the PMSGs in our data-file use direct drive to impart rotation into their power-dense magnets (no gears). Almost all of the IGBT turbines use gears, to step up the rotational speed by around 100:1, on average. Some PMSGs retain gears in order to lower the amount of Rare Earth materials/magnets required by up 90% (e.g. Vestas).

More compact turbines are associated with PMSGs, and this is an advantage, as it lowers the costs associated with wind turbine installation and offers faster commissioning.

Fault ride-through is one of the most commonly cited issues for using Rare Earth PMSGs rather than DFIG turbines. A DFIG requires a power connection to magnetize the electromagnets in its rotor. If the power input drops, then the power output also drops.

Chinese manufacturers have been gravitating towards PMSGs especially since 2016. For example when Goldwind switched from DFIGs to PMSGs, the company noted it was able to eliminate 13 gears and “hundreds of parts”.

Vestas and GE have been relatively vocal about benefits of permanent magnets. GE back to 1998 (!). Vestas is now using Rare Earth elements in all new grid turbine models (per the Vestas website here).

Conversely, two other European manufacturers stand out as they have been more reluctant to use permanent magnets, and more focused on DFIG designs, especially in smaller turbines and onshore turbines.

Our forecasts for Rare Earth magnet use in future wind turbine’s bill of materials, both in mass terms (kg/kW) and in cost terms ($/kW) is modelled here.

Underlying data behind these observations is set out in the data-file of wind turbine generators. If you want to understand how magnets in wind turbines work, we recommend our overview of magnets. All of our broader wind research is here.