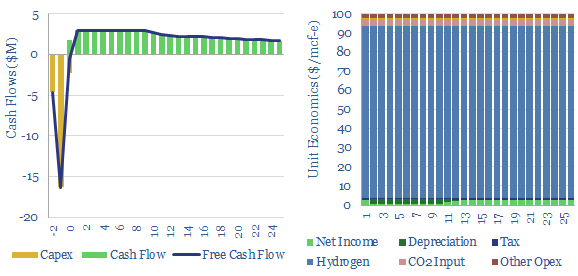

…$3.5/mcf hub gas prices (and by extension, $4.5-5.5/mcf input gas prices), in our model of NET Power’s oxy-combustion process linked here. The usual caveats apply that levelized cost calculations can…

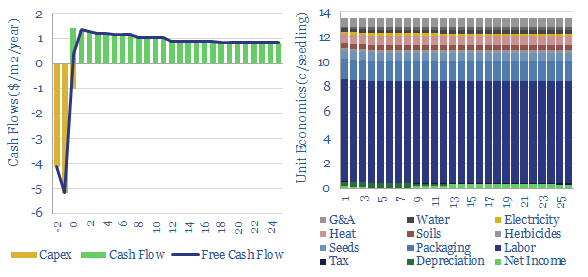

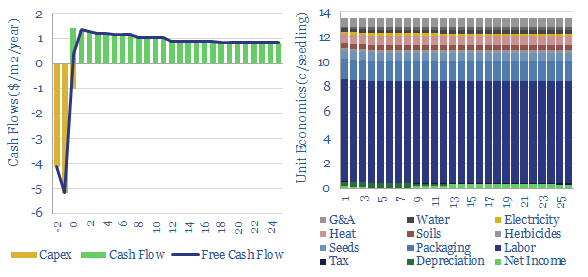

…warmer climates, have a typical cost of 7c/seedling. Conversely, in colder climates, seedlings maybe grown in containers, in heated greenhouses, which also has the advantage of permitting earlier growing and…

…be the focus for new investment in the company’s EUR 300M capex plans. Is there value in bio-energy technology? We see persistent shortages of hydrocarbons in the 2020s (model here)….

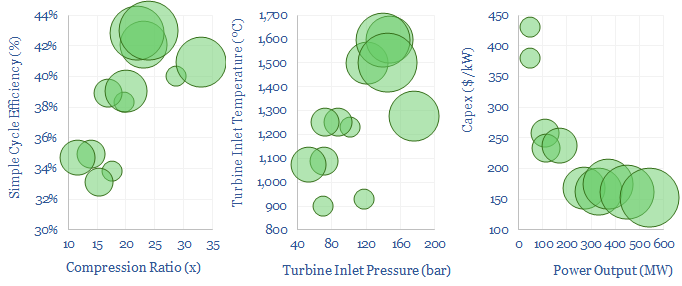

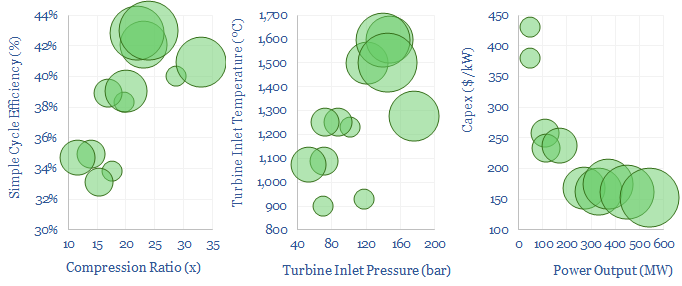

…note that our model of a gas-fired power plant assumes total capex of $850/kW. In other words, total installed capital costs are typically around 4x larger than the turbine itself….

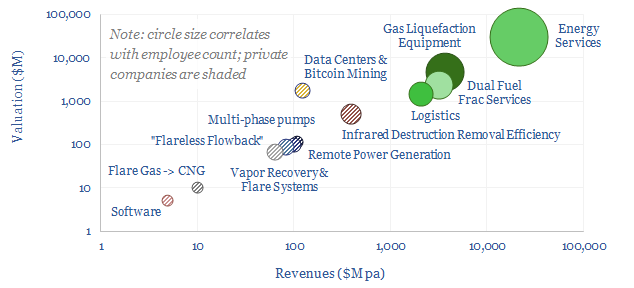

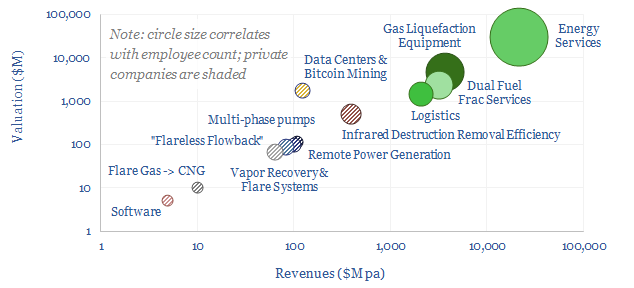

…of their technology. But this is just a sample of names, to illustrate the breadth of the theme. Breadth and the giant furnace model. There is a dangerous temptation to…

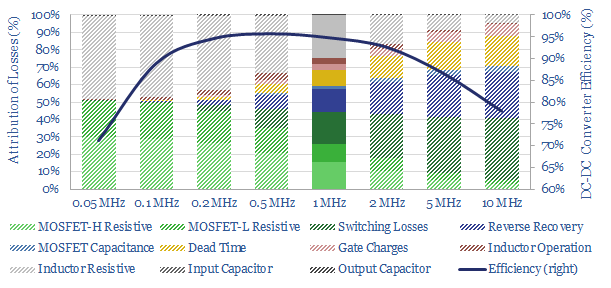

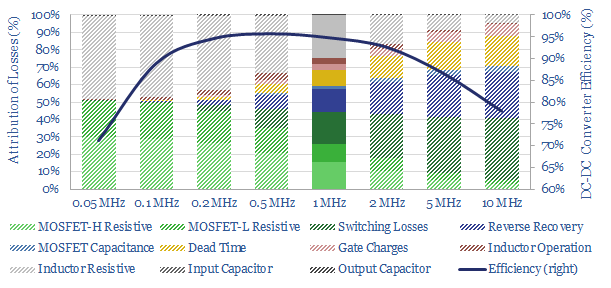

…Switching. Step-up or step-down ratio. In our model, we have captured a buck converter, where in the base case, the voltage is being stepped down by 50%. This is what…

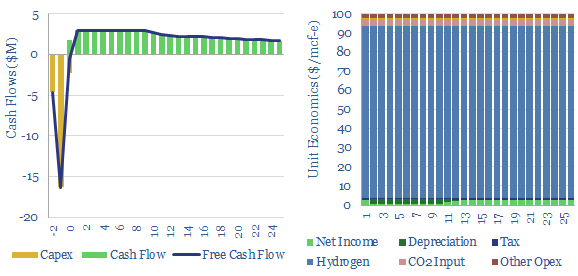

…a LNG plant but lower than a petrochemicals plant (models here). Costs are 90% dominated by green hydrogen input costs, which we have penciled in at $7.5/kg, in line with…

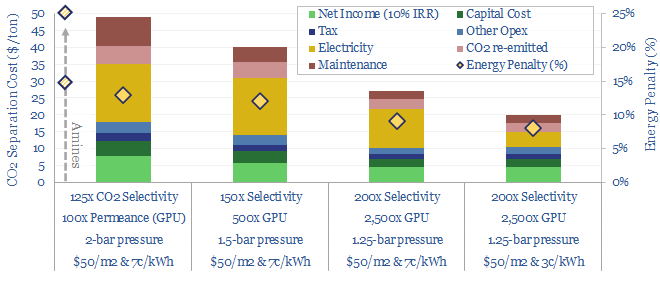

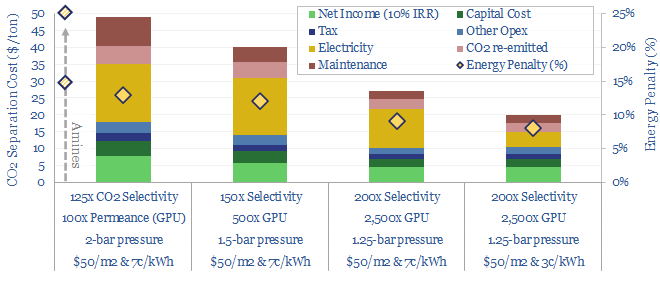

…mind, if they are appraising next-generation membranes for CCS. I.e., what kinds of numbers start to get exciting, across the key dimensions, to unlock $20-50/ton separation costs (model here). Important…

…a breakthrough in membrane CCS, backed up by an economic model here. Membrane Technology and Research Inc. has developed a membrane system called Polaris, with 50x CO2:N2 selectivity, and very…

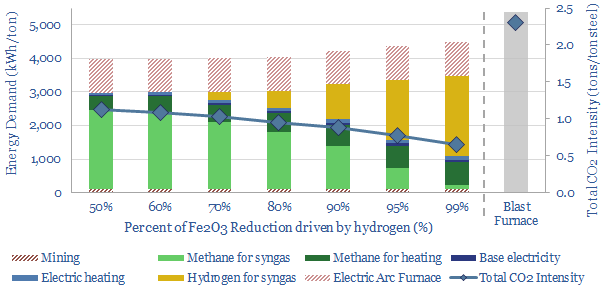

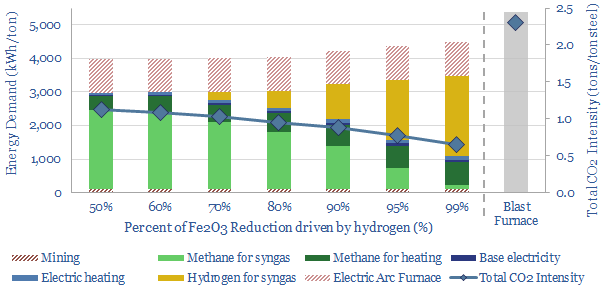

…of CO2 per ton of finished steel (model here) (page 5). Technological maturity is another factor. DRI+EAF is an alternate steel-making pathway, which already underpins 120MTpa of global steel production….