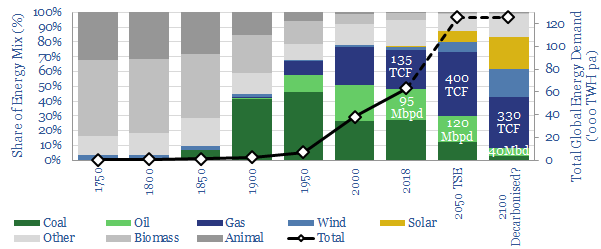

We are positive on the opportunity to de-carbonise gas-fired power generation using next-generation combustion technologies, such as oxy-combustion, which is reviewed in our deep-dive note, ‘Decarbonising Carbon‘. Could the same technology be used in automobiles? It is more difficult. But the world’s largest oil company is nevertheless trying.

[restrict]

Oxy-Combustion aims to obviate the challenging step of separating CO2 from exhaust gas by burning fuels in an atmosphere that has been purged of Nitrogen (e.g., pure oxygen and CO2). This means that the exhaust gas will comprise CO2 and H20 (i.e., no nitrogen). It can readily be de-hydrated and the CO2 can be sequestered.

(In thermodynamic terms, this requires using a mechanical cycle such as the Allam Cycle in lieu or the traditional Otto Cycle or Diesel Cycle).

This technology works. It is being trialled at three power facilities globally, to decarbonise heat and power. One very promising industry-leader is backed by Occidental. The opportunity of economically de-carbonising gas is extremely positive for global gas demand, as reflected in our own models (chart below, download here).

But could oxy-combustion be used to de-carbonise oil-fired transportation?

In our review of 3,000 patents around the industry, Saudi Aramco stands out as the company working hardest to reduce the emissions of oil-fired transportation. It published over a dozen novel vehicle designs last year (details available to ThunderSaid clients).

Almost all of its efforts aim to reduce the CO2 intensity of burning liquid fuels in auto-engines. Those using oxy-combustion go back to 2013. They have been filed in multiple geographies and updated repeatedly in 2019.

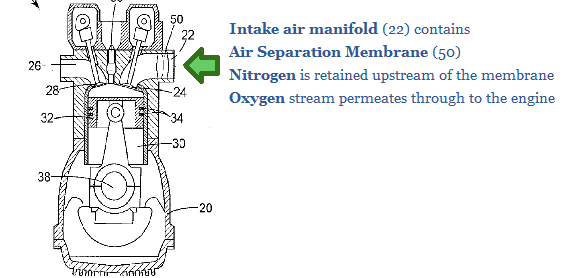

The rationale is to reduce emissions from mobile sources, which comprise 25% of global CO2 and to prevent the formation of NOXs by restricting Nitrogen from the engine. One patent states: “Since pure or nearly pure 02 is combusted with the fuel, the resulting combustion product will constitute principally C02 and H20. The water can readily be condensed and separated to provide a pure, or nearly pure CO2 stream for densification and storage.”

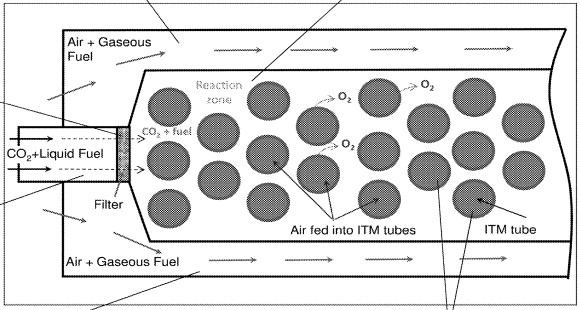

The challenge with oxy-combustion is to purify the oxygen prior to combustion. Aramco’s approach is to achieve this task using electro-ceramic membranes, as commercialised by Ceramatech of Salt Lake City, Utah and Air Products. Aramco has also patented its own membrane cell designs (image below).

The drawback is that these membranes require high temperatures (700-800F). But Aramco’s patent notes this need not be problematic in an internal combustion engine, where c60% of the energy in fuels is converted into heat in to the engine, at 600-650C.

Thus a schematic of the proposed oxy-combustion engine is shown below, including a specially-enlarged air intake, and a membrane to separate N2 from O2.

Can Oxy-Combustion Vehicles be Commercialised?

Challenges of deploying oxy-combustion in a mobile vehicle are not overlooked by the patents.

(1) Space and weight limitations are more acute in a small, mobile vehicle than they are in a fixed power facility. Hence “a major problem … is how to minimize the additional weight and space required by air separation components” in, say, a car.

(2) Storing CO2 on board the mobile vehicle will be necessary, until it can be discharged at a disposal facility. This requires compression energy, to pressure the CO2 to 5-1,600kg/m3. There may be limited storage space. A network of CO2 disposal sites would also need to be developed alongside fuel retail stations.

(3) System stability. The electro-ceramic cells used to separate N2 and O2 have “capacity to produce high-purity O2 over thousands of hours”. But it is not clear whether they will work under extreme temperature variations. The cells may also degrade over time, given the complex chemistry of the electro-ceramic cells: e.g., doped cerium oxide electrolyte, sintered lanthanum strontium cobalite electrodes covered with silver.

(4) System sufficiency. In some high-intensity conditions — hills, motorways — Aramco’s patents acknowledge it will still be necessary to introduce N2 to the engine, emitting NOXs and CO2.

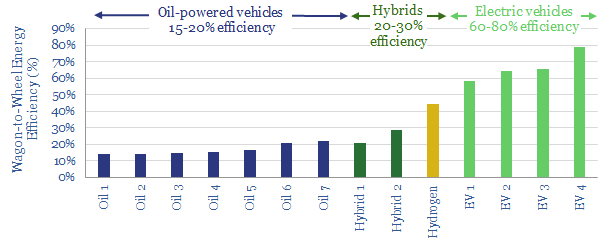

(5) Competition with electric vehicles. Finally, the fundamental energy efficiency of combustion remains c20-30%, compared with 60-80% for electric vehicles (chart below, data here). Electric vehicles have an order-of-magnitude fewer parts, whereas oxy-combustion vehicles appear to have many more.

[/restrict]

We conclude there is strong potential to de-carbonise gas-fired power generation with next-generation combustion technologies. But de-carbonising oil-fired automobiles may be most readily accomplished by electrification, i.e., substituting in smaller, more-specialised electric alternatives.

Source: Hamad, E. Z. & Al-Sadat, W. I. (2013). Apparatus and Method for Oxy-Combustion of Fuels in Internal Combustion Engines. Saudi Aramco Patent WO2013142469A1.

Source 2: Ben-Mansour, H., Habib, M., Jamal, A. (2017). Gas-Assisted Liquid Fuel Oxygen Reactor. Saudi Aramco Patent US2017284661