Petrobras has patented next-generation riser designs, to handle sour-service crude from pre-salt Brazil. This is needed after prior cases of riser-failure, e.g., at Lula. Its new solution could also support development of higher-CO2 fields, such as Libra. But complexity is an order of magnitude higher. A simpler alternative is the growing potential from thermo-plastic composite pipe, which resists corrosion and is 45% more economical than conventional risers.

Pre-salt riser failures from CO2-corrosion

In 2017, Upstream Newspaper reported that Petrobras had suffered two riser failures, injecting high-CO2 gas back into the Lula and Sapinhoa reservoirs. The failures occurred after just 3-years, at risers designed to last for 25.

These failures were induced by stress-corrosion, which in turn derives from the high CO2 content in the pre-salt. For example, CO2 is reported at 8-12% at Lula.

As Petrobras moves to develop even higher-CO2 fields, such as Mero (Libra), where the gas is up to 30% CO2, it has also sought to minimise the use of flexible risers, to protect against corrosion.

New solutions… new challenges?

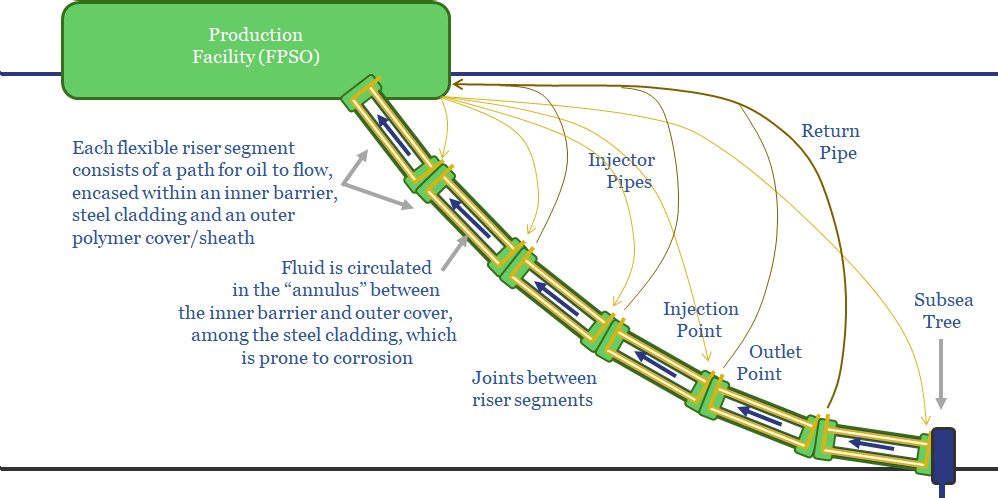

Improved riser solutions feature prominently in Petrobras’s 2018 patent filings, which we have reviewed. One patent localises the problem of stress-corrosion to the risers’ steel cladding, which is situated in the annulus between the riser’s barrier layer and outer sheath. The barrier layer can sometimes be breached by fluids moving through the riser.

Petrobras states:“Stress corrosion is caused by CO2 and not well-covered by international standards for flexible pipes...there is normally no way to displace gases from the annulus or minimise their corrosive effects”.

It is noted that Chevron, Schlumberger and GE have all patent solutions to detect the presence of corrosive fluids reaching the steel cladding of a riser. However, to mitigate this problem, comprehensively, in a flexible, deep-water riser with many segments, Petrobras has filed its own solution (chart below).

Inert fluids are envisaged to be swept through the annulus of the riser, removing any corrosive fluids that have accumulated. The fluid is forced through each independent segment of pipe. Leak tests can be performed to detect damaged sections.

Another argument for composites?

What strikes us about Petrobras’s solution is the added complexity. As pictured above, it will be necessary to maintain a flow of anti-corrosive fluids through each riser segment, via an additional series of injection pipes and return pipes. All of these must be fabricated, installed and maintained.

After weighing up the additional complexity of circulating anti-corrosive fluids through the cladding of flexible pipelines, we grow more positive on the relative simplicity of an alternative: themo-plastic composite risers (TCP).

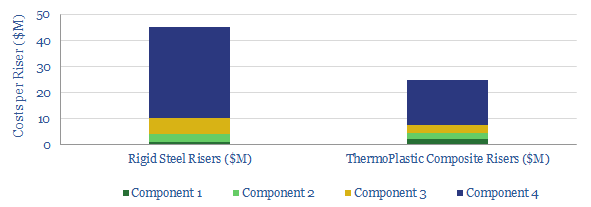

These next-generation materials are corrosion-resistant, withstanding CO2 concentrations up to 50% and H2S up to 200ppm. They also deliver comparable strength to steel, at 10% of the weight, which simplifies their installation and lowers overall costs for a riser system by 45% (chart below).

For our data-file quantifying the progress-to-date and the costs of TCP, please see here.

Source: Carpigiani de Almeida, M., Cameiro Campello, G., Ribeiro, J., Mello Sobreira, R. G., Loureiro Junior, W. C. & Piza Paes, M. T. (2018). System and Method for Forced Circulation of Fluids Through the Annulus of a Flexible Pipe. Petrobras Patent 2018220361.