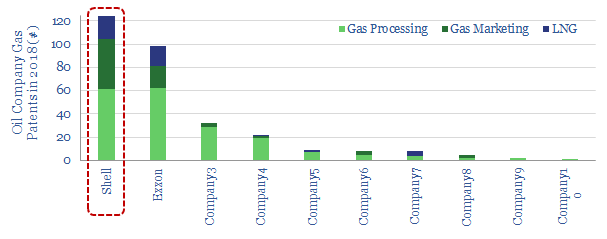

Shell is the leading Major in driving new LNG demand, based on patent filings (chart above). As an example, we highlight a leading new technology to promote LNG demand in transportation, by mitigating the problem of boil-off.

[restrict]

What is limiting LNG in transport?

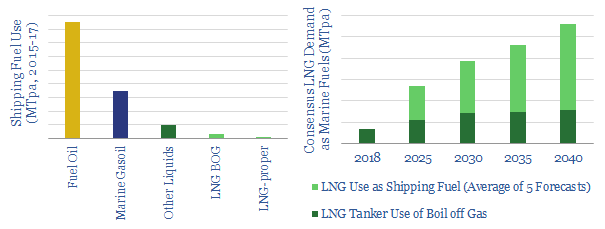

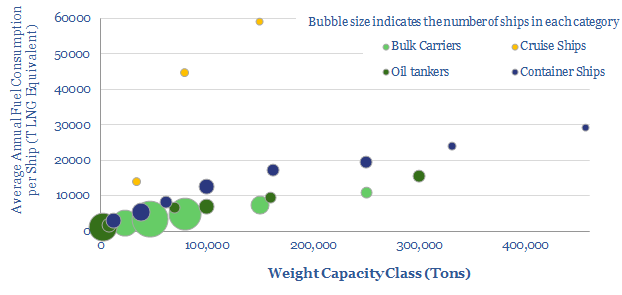

LNG’s potential upside in transportation is exciting, particularly in shipping, as technologies improve and new sulphur regulation sweeps through the maritime industry (chart below, for full details see our deep-dive note, LNG in Transport: Scaling Up by Scaling Down). But challenges must also be acknowledged.

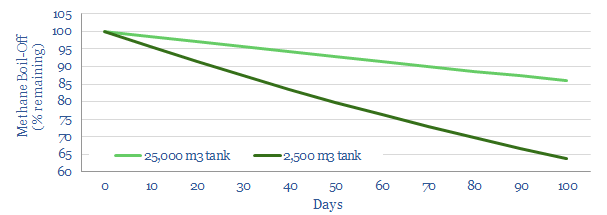

Most prominent is boil-off of LNG, which inhibits its storage over long time-frames. Boil-off typically runs at 0.15% per day, in a large, 25,000m3 tank, which means that c15% of the cargo would be lost over a 100-day period. For smaller-scale LNG, the rate is steeper, averaging c0.45% per day for a 2,500m3 tank, which in turn would cost c35% of the cargo over a 100-day period (chart below). In extremis, 1% per day boil-off is not unheard of.

Managing boil-off requires a vapor management system. Otherwise, as liquid evaporates into gas, the pressure exerted gradually rises, and eventually there is risk of exceeding the tank’s design pressure. This one one reason for the additional costs of converting a vessel to run on LNG, which can reach $17-35M for the largest tankers.

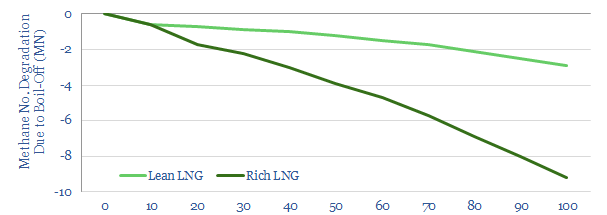

Gas Weathering is another challenge, less well-known, but crucially important. LNG is a mixture of hydrocarbon gases, all with different boiling points. Lower boiling-point components vaporize more readily. Hence over time, the higher boiling point constituents become more concentrated in the fuel tank, lowering the “methane number” of the fuel (chart below). This causes challenges. Most engine makers specify methane must comprise >80% of the fuel in a gas-fired engine. Below this level, the engine performs sub-optimally, knocking, misfiring, over-heating and potentially damaging components such as piston crowns and exhaust valves.

Shell’s improvements: a sub-cooler

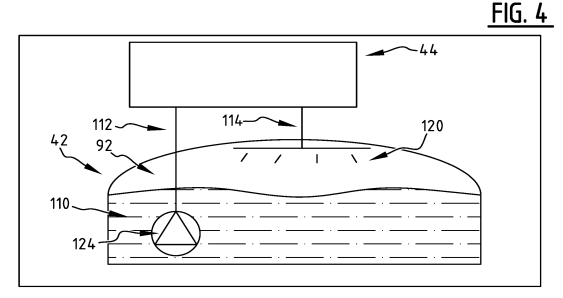

To support LNG’s ascent in transportation, Shell has been the most active Major in developing new technologies. We will be elaborate further, in our upcoming research. But in 2019, one patent stands out, as the company has developed a new ‘sub-cooler’ (pictured below), to met the challenges described above.

The sub-cooler (44) is fluidly connected to the LNG storage tank (42) on a LNG-powered vessel. The tank’s temperature is continually monitored. When it exceeds a predetermined upper threshold, by say 0.25C, a small volume of LNG is pumped out (through 112) , sub-cooled (in 44) then sprayed back into the tank’s vapor space (via 114), until the tank is cooled back below a lower threshold, say, 1C below methane’s boiling point.

The invention’s equipment includes a compressor, a turbine, two heat-exchangers and use of the Brayton Cycle, most likely Air Liquide’s Turbo-Brayton refrigeration cycle using Nitrogen and/or Helium. Its advantage is reliability and low maintenance, which matter for long voyages.

Eight Advantages are Cited

- Storage capacity is increased by providing constant and continuous vapor management, using the sub-cooling system.

- Weathering is prevented, by sub-cooling and recycling liquefied gas, thus preserving the composition of the liquefied gas.

- Fuel economy is thus maximised by avoiding the sub-optimal fuel-consumption caused by weathering. Shell states “Utilization of this system on gas fueled vessels will also allow for greenhouse gas emissions to be optimized”.

- Longer journeys are thereby made more feasible.

- Capex is saved. By employing Shell’s sub-cooler, no auxiliary consumer is required, lowering the cost of the system, potentially elminating GVU units, control valves, double wall piping, and labor and installation costs.

- Opex may improve, due to better fuel economy, and as a larger range of input fuels can be used,

- Safety is improved during transfer of LNG from a discharging tank to a receiving tank, providing the ability to lower temperature to 0.5-3C below the gas’s boiling temperature and “thereby limit flashing in the receiving tank during transfer”.

- Versatility. The system can be installed in new LNG-powered vessels, new conversion of diesel vessels or retro-fitted onto existing LNG vessels. It can also be deployed in a broad range of LNG-transportation concepts (the patent mentions cruise ships, tankers, container vessels, ferries, barges, tugs… and more exotically, rail, truck, car and even planes!).

Economic Impacts to spur the ascent of gas?

The improvements above may stoke the ascent of LNG for shipping, where we are most positive with 40-60MTpa of upside seen to LNG demand after 2040 (see LNG in Transport: Scaling Up by Scaling Down).

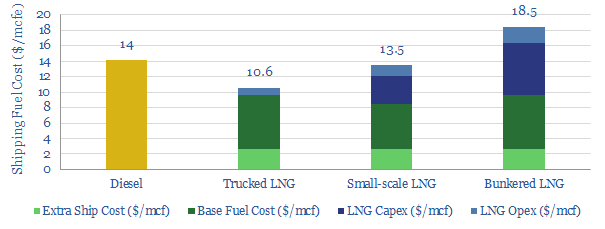

Small-scale liquefaction for shipping is already going to be highly economical after IMO 2020, while bunkered LNG can be rendered as economic if it can harness economies of scale (model here).

The most attractive vessels to convert to run on LNG are cruisers and large container ships (data-file here).

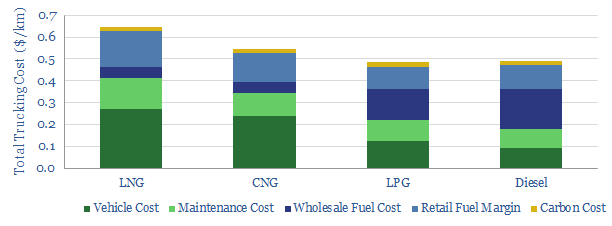

Economics are currently more challenging for LNG trucks (model here). However, this is due to 2.5x higher vehicle costs and 2x higher maintenance costs per mile. But technical progress such as Shell’s will help.

Source: Hutchins, W. R. & Hartman, S. J. S. (2019). Liquid Fuel Gas System and Method. Royal Dutch Shell Patent US2019024847

[/restrict]