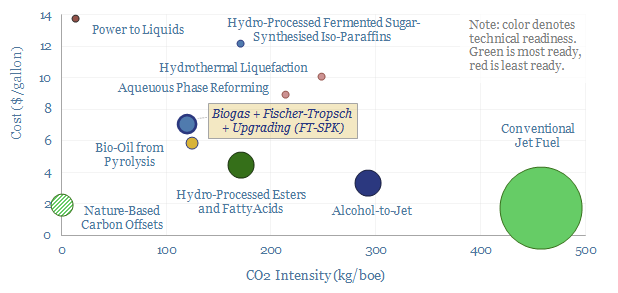

This 15-page report evaluates a pathway for sustainable aviation fuels, feeding biogas into a Fischer-Tropsch reactor. Three projects are in progress. But bio-GTL will likely cost 3x more than conventional jet, for a 75% reduction in CO2, giving an abatement cost of $550/ton. Moreover, the same biomass feedstock could abate 4x more CO2 via other pathways. We still prefer nature-based carbon offsets for aviation.

Three biogas to liquids projects are in progress to help decarbonize aviation fuels. Each project is briefly outlined on page 2.

Our framework for modelling the cost of bio-GTL is explained on page 3, to see whether the technology is attractive.

Biogas production and sweetening are modeled on pages 4-5. We note the importance of policy and the challenge of achieving large-scale production.

The GTL process is modeled on pages 6-10. We focus on the costs, economics, CO2 intensities and liquid yields.

Heavy subsidies are needed to make biogas-to-liquids cost-competitive, most likely in the form of landfill taxes, which must run well over $100/ton, as argued on page 11.

Our main challenge is the carbon accounting, outlined on pages 12-13. We find other biomass pathways could abate 4x more CO2 emissions compared with bio-GTL.

Reactor up-time may also be a further technical risk, based on our review of technical papers, and discussed on page 14.

Our conclusion is that nature-based solutions to climate change are superior to sustainable aviation fuels. They can offset 100% of the CO2 for a cost of $3-50/ton.