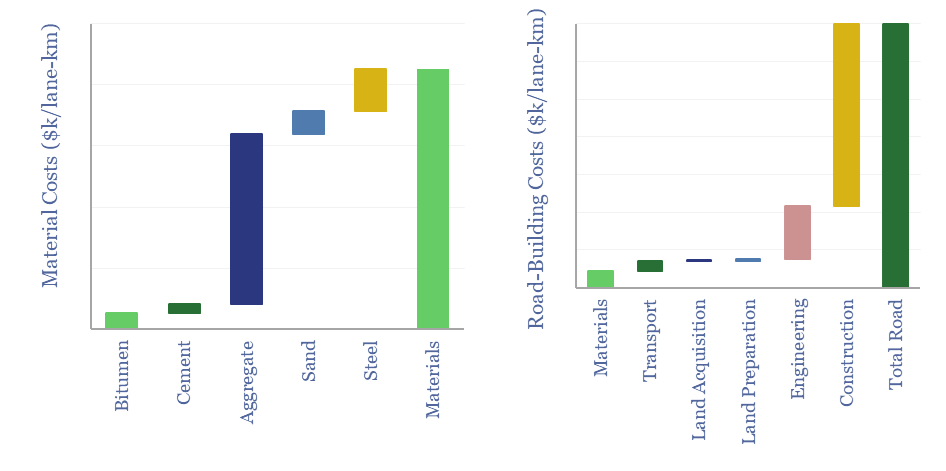

A typical road costs $3M/lane-km to construct, with an effective cost of $0.25 per vehicle-km subsequently travelled. The range varies with utilization and road complexity. Around 10% of the costs are materials, mainly aggregates, while the remainder of the capex is spent on construction and engineering.

Road costs matter as an input to other economic models, as building any new piece of infrastructure requires access to that infrastructure, whether it is a wind farm, solar project, power transmission line or any other industrial facility.

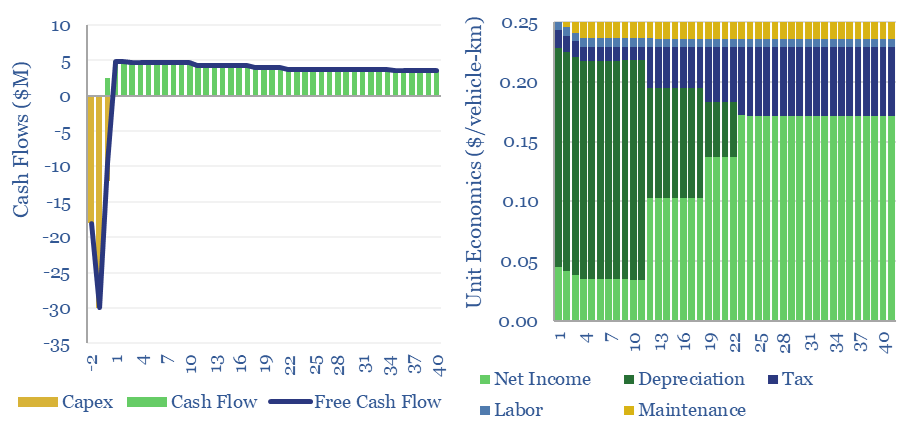

Our economic model captures a road as though it were an economic entity, charging $0.25 per vehicle-km, to generate a 6.5% IRR on $3M/lane-km of capex. Of course, built by governments, there is no tax charge. Eliminating the tax charge boosts the IRR to 7.5% at the same road cost. Or alternatively, it reduces the ‘road cost’ by c10% for the same IRR.

In other words, the average American derives $4,000 of ‘road value’ as they drive 10,000 miles per year. To put this number in perspective, most of the US’s inter-state highway system was built during Eisenhower’s $620bn highway-building initiative from 1956-1990, possibly one of the best infrastructure-investments ever made. These roads are largely depreciated today. Although the US continues to spend $250bn pa, or $750 per American, maintaining and enhancing the road network.

The capex costs of a road vary with complexity. The cheapest roads cost $1M/lane-km. Roads with more junctions, bridges, overpasses or tunnels might be in the range of $5-10M/km. Land costs matter too, as per other infrastructure.

Around 10% of road costs are materials, especially aggregates and/or sand (15,000 tons per lane-km), followed by steel (35 tons per lane-km), bitumen (85 tons/lane-km) and cement (60 tons/lane-km). And materially more for large highways. The material must also be transported to site which maybe accounts for $20/ton of material in a large hauler.

Leading companies producing aggregate materials for road-building include Vulcan Materials, Martin Marietta and leading-cement producers, such as CRH, Heidbelerg and LafargeHolcim.

Capex costs also vary with the size of the road. For example, the material intensities can vary by a factor of 2x between smaller and larger roads, categorized by road layer thicknesses.

The costs per vehicle also depend on road utilization. The US sees 3.3 trn vehicle miles per year, across 4.2M miles of roads, which means each road is driven once every 40-seconds. We are effectively using this same cadence in our models. But doubling/halving the amount of vehicle traffic, all else equal, halves/doubles the effective road cost per vehicle.