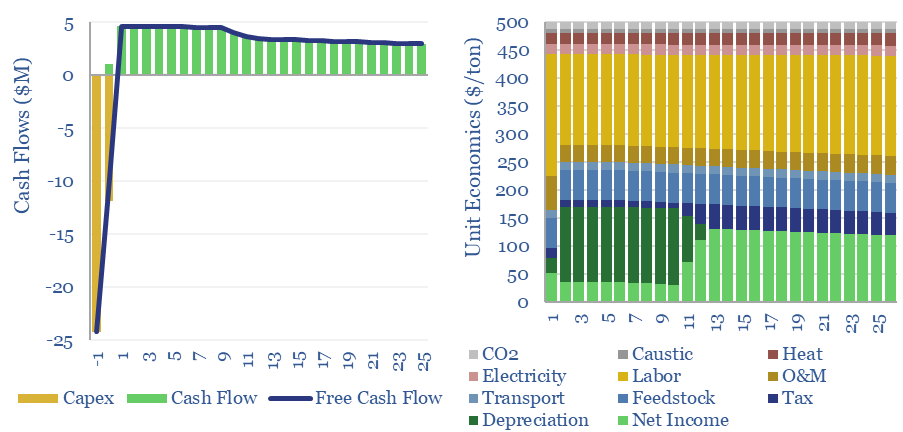

Plastic recycling requires a $500/ton product price, to earn a 10% IRR off of c$1,000/Tpa of up-front capex, at a mechanical recycling facility with 0.3 tons/ton of CO2 intensity (up to 80-90% below virgin plastics, more than we expected). This data-file captures the economics and the costs of plastic recycling, especially for the mechanical recycling of PET.

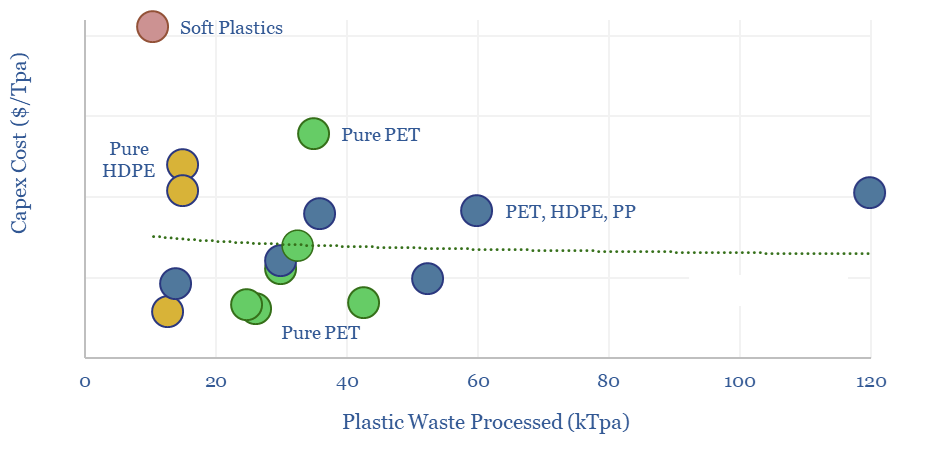

10% of today’s end-of-life plastic is recycled, or around 40MTpa, within the global plastics industry. Substantively all of this is mechanical recycling, particularly for PET and HDPE, but also to a lesser extent, polypropylene, PVC and to an even lesser extent, polystyrenes.

Mechanical recycling of plastics starts by aggregating plastic waste into bales, transporting to a recycling facility (possibly via truck), then shredding. Next come successive stages of sorting, washing and drying, before clean plastics of the same grade are melted and re-pelletized.

Early sorting stages are aimed at removing paper and dirt, while later stages group plastics of similar optical properties. Washing stages may use caustic soda from the chlor-alkali process. Drying may also be used to char off contaminants.

Capex costs vary, facility-by-facility, but are built up in the data-file via surveying past projects. Energy costs also vary, hence the electricity use of plastic recycling (in kWh/ton) and the heat use (also in kWh/ton) are also built up by surveying technical papers.

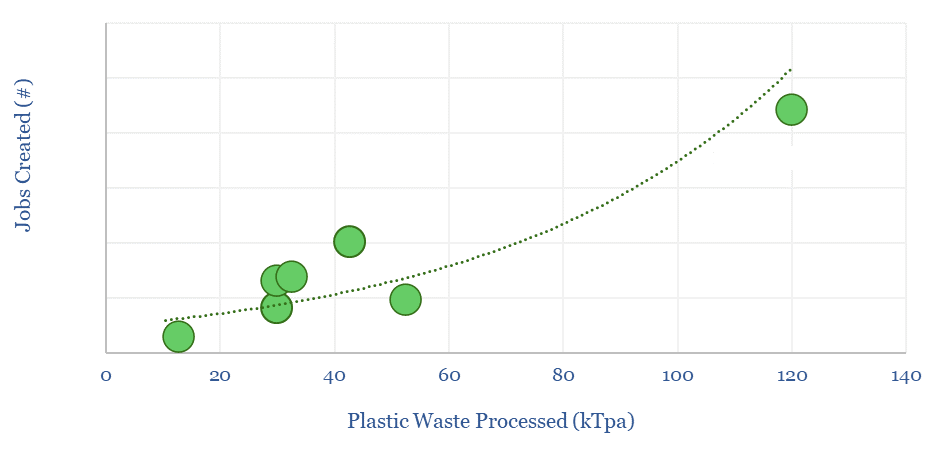

The largest opex cost line in the model is labor, due to the need for precise sorting of waste materials. Labor intensity of plastic recycling is based on the disclosures from past projects.

Finally, economics are sensitive to transportation distances. Our model allows for plastic waste to be moved up to 50-miles, however higher prices are needed, for transport over longer distances.

Please download this data-file to stress-test the costs of plastic recycling, by varying the capex, opex, utilization, labor rates, feedstock costs, electricity prices, heat prices, CO2 costs plus taxes and incentives.

In our broader research, we have also explored chemical recycling of plastics, via plastic pyrolysis, and other existing and next-generation recycling technologies. For more on our outlook for polymers, please see our overview of plastics in the energy transition.