Global production of chlorine reached 80MTpa in 2021, while global production of caustic soda reached 90MTpa. Both are products of the chlor-alkali process, electrolysing sodium chloride solution. This data-file captures chlor-alkali process economics, to derive costs in $/ton of each commodity.

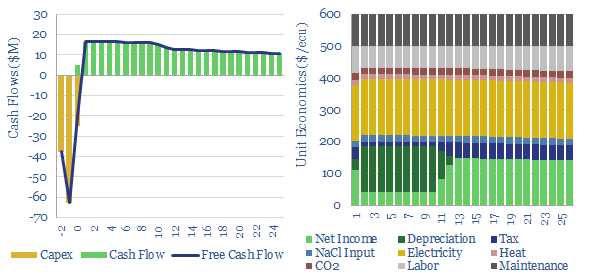

Our base case model requires revenues of $600 per ecu (electro-chemical unit), which in turn comprises 1.13 tons of NaOH, 1 ton of Cl2 and 0.03 tons of H2 gas. This generates a 10% IRR of a low cost growth project costing $600/Tpa. Costs would be somewhat higher at pure greenfields, especially in higher-capex geographies (e.g., the US).

Costs matter as chlorine, NaOH and their derivatives are inputs to many of our other economic models for energy transition and broader industrial models, such as paper products, renewable diesel, carbon fiber, refining, battery recycling, some CCS and Direct Air Capture. HCl is also an input to the Siemens Process, used to make 92% of the world’s PV silicon in 2021.

Energy intensity is middling. Electricity comprises 30% of the total marginal cost, and c45% of cash cost, under our base case assumptions. CO2 intensity is 0.5 tons of CO2 per ton of product.

Interestingly, chlor-alkali plants may be able to demand shift, cutting 20-30% of their electricity consumption in times when renewables are not generating. You can stress-test chlor-alkali process economics in the data-file.

To read more about the chlor-alkali process, please see our article here.