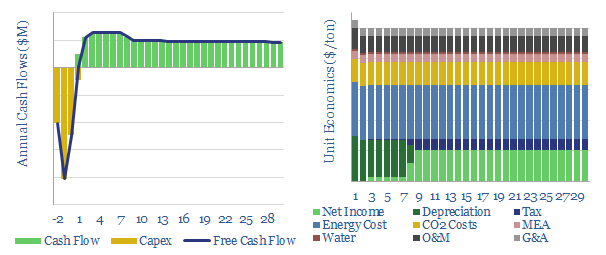

This data-file models the costs of amine process CCS, capturing post-combustion CO2 from exhaust gases using amines, in order to calculate what CO2 price is necessary to earn a passable IRR. This is one of three components of a CCS project, alongside CO2 transport and CO2 sequestration.

Input assumptions for the costs of amine process CCS can be flexed in cells H5:35 of the model, in order to stress test the sensitivity to gas prices, energy efficiency, amine costs, water costs, capex, G&A and fiscal conditions.

Our own base case estimates are informed by five tabs of cost data and technical papers. While we have also developed a rough scenario for deploying CCS on a large ship.

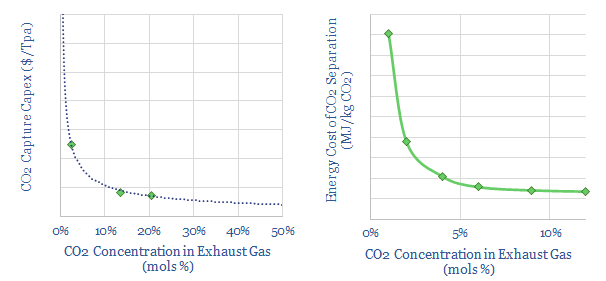

CO2 costs are extremely sensitive to CO2 concentrations, rising exponentially if it is necessary to capture CO2 from more diffuse sources. The typical CO2 concentrations of different exhaust streams are tabulated in another of our data-files, here.

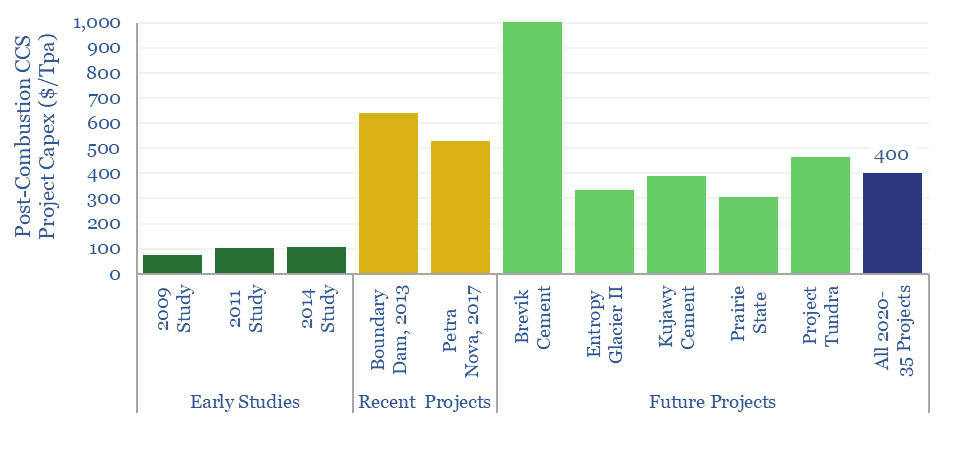

Our base case costs for post-combustion CCS are generous as we are not including additional gas-cleaning upstream of the amine unit such as dust removal via ESPs, sulfur removal via scrubbers, or NOx removal via SCRs, all of which may be necessary to prevent dangerous amine degradation and emissions. This note is worth reading.

In 2024, we have raised our estimates for the costs of amine based-CCS, after reviewing the actual capex budgets, across representative projects from our global CCS projects database. Studies that we had reviewed in 2019-20 suggested capex costs of $100/Tpa. But including the additional equipment, noted above, real-world projects are closer to $400/Tpa (below). This one change raises our marginal cost for post-combustion capture at an amine plant from c$40/ton to $90/ton.

Energy penalties of post-combustion CCS are also calculated in the data-file, as a function of electricity use (kWh/ton), amine regeneration energy (GJ/ton), different fuel types, combustion efficiencies and waste heat recapture ratios (chart below). We think energy penalties can range from 15-70%. This is discussed in our recent research note.