Search results for: “electric arc furnace”

-

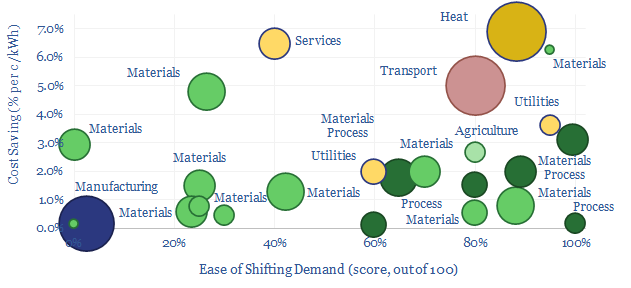

Demand shifting: electrical flexibility by industry?

Demand shifting flexes electrical loads in a power grid, to smooth volatility and absorb more renewables. This database scores technical potential and economical potential of different electricity-consuming processes to shift demand, across materials, manufacturing, industrial heat, transportation, utilities, residential HVAC and commercial loads.

-

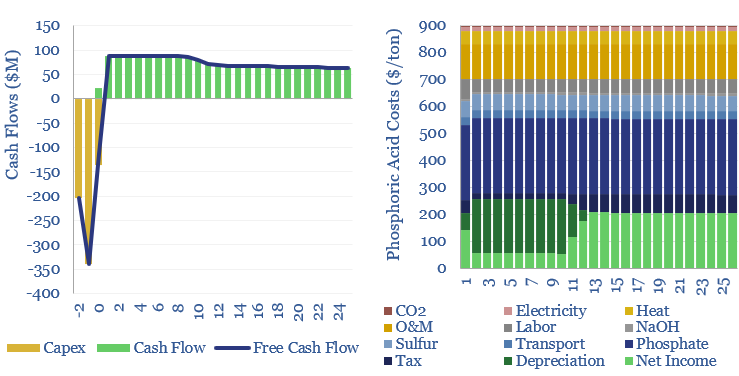

Phosphoric acid production costs?

Phosphoric acid production costs are $500-900/ton, for a 10% IRR on a new facility, with $1,000-2,000/Tpa of capex. This is using the ‘wet process’, where phosphate ores are reacted with sulfuric acid. CO2 intensity is 0.6 tons/ton. However, the numbers depend on product purity. There is also a 10x higher carbon, yet potentially lower-cost process,…

-

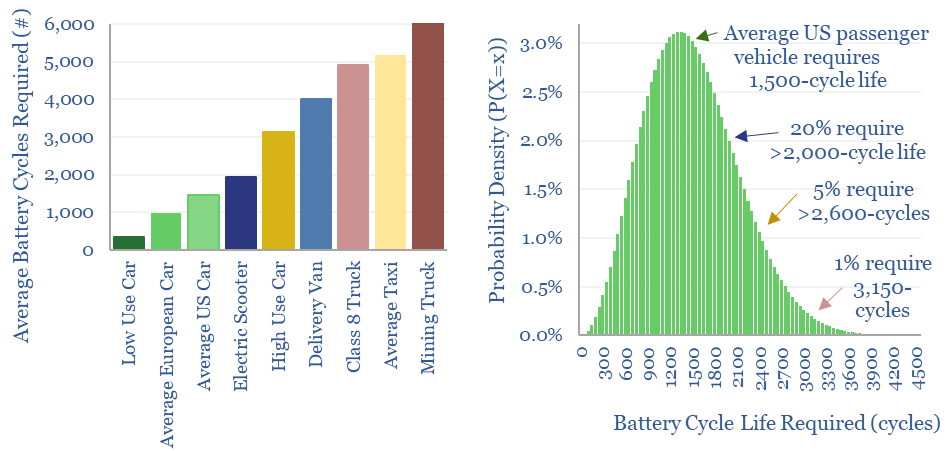

Electric vehicle: battery life?

Electric vehicle battery life will realistically need to reach 1,500 cycles for the average passenger vehicle, 2,000-3,000 cycles after reflecting a margin of safety for real-world statistical distributions, and 3,000-6,000 cycles for higher-use commercial vehicles. This means lithium ion batteries may be harder to displace with novel chemistries?

-

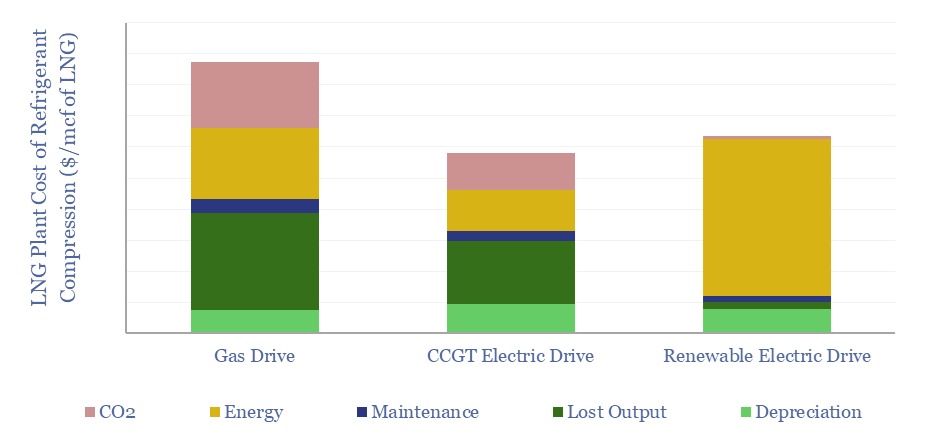

LNG plant compression: gas drives vs electric motors?

This data-file compares the costs of refrigerant compression at LNG plants, using gas turbines, electric motors powered by on-site CCGTs, or electric motors powered by renewable electricity. eLNG has higher capex costs, but higher efficiency, lower opex, and short payback times. Numbers in $/mcf and $/MTpa can be stress-tested in the data-file.

-

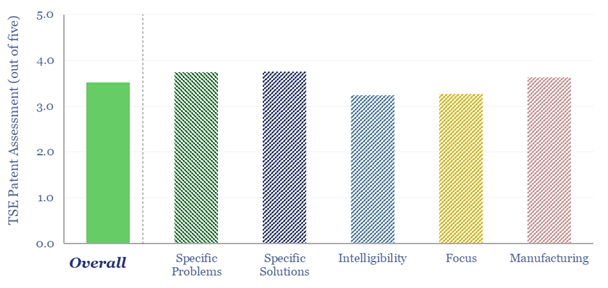

Shanghai Electric: gas turbine technology competition?

Shanghai Electric gas turbine technology is contrasted against the Western gas turbine leaders in this data-file, based on reviewing 20 patents from 2021-24. Shanghai Electric is clearly trying to compete in this space, and the patent review uncovered interesting details into turbine temperatures, efficiencies, reliability, AI+sensing and manufacturing costs.

-

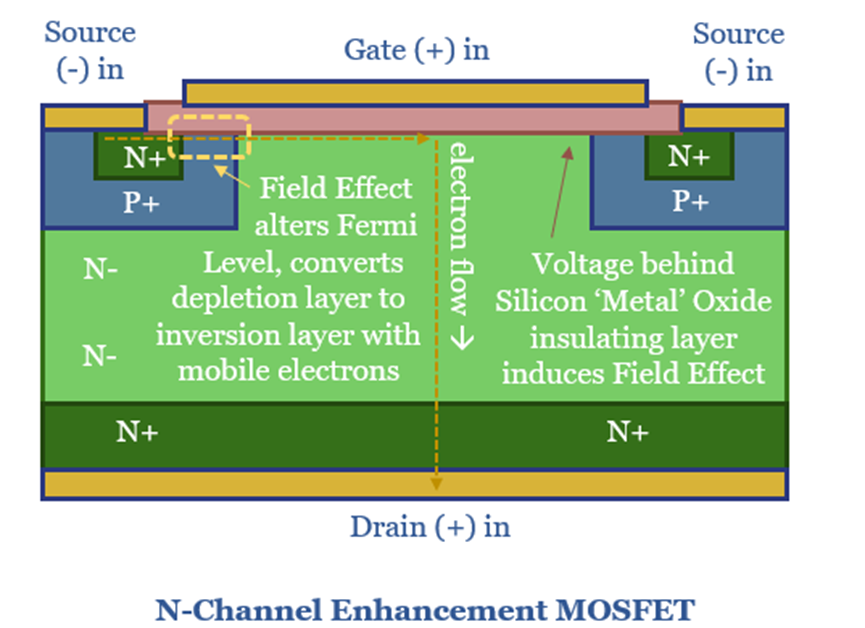

Semiconductors: outlook in energy transition?

Semiconductors are an energy technology. And they are transforming the future global energy complex, across AI, solar, electric vehicles, LEDs and other new energies. This short article summarizes our outlook for semiconductors in energy transition, and resultant opportunities across our work.

Content by Category

- Batteries (89)

- Biofuels (44)

- Carbon Intensity (49)

- CCS (63)

- CO2 Removals (9)

- Coal (38)

- Company Diligence (94)

- Data Models (838)

- Decarbonization (160)

- Demand (110)

- Digital (59)

- Downstream (44)

- Economic Model (204)

- Energy Efficiency (75)

- Hydrogen (63)

- Industry Data (279)

- LNG (48)

- Materials (82)

- Metals (80)

- Midstream (43)

- Natural Gas (148)

- Nature (76)

- Nuclear (23)

- Oil (164)

- Patents (38)

- Plastics (44)

- Power Grids (130)

- Renewables (149)

- Screen (117)

- Semiconductors (32)

- Shale (51)

- Solar (68)

- Supply-Demand (45)

- Vehicles (90)

- Wind (44)

- Written Research (354)